From Blueprint to Reality: A Day in the Life at ACCO Industrial Construction Company

| Main Topics | Subtopics |

|---|---|

| H1: Introduction | Overview of Faisalabad’s Industrial History and ACCO’s Role in Modernization |

| H2: Faisalabad’s Industrial Background | The Evolution of Faisalabad as Pakistan’s Industrial Hub, Key Sectors Driving Growth, Pre-ACCO Development Challenges |

| H2: The Rise of ACCO in Pakistan | Company Background, ACCO’s Vision for Construction in Faisalabad, Initial Projects that Set the Foundation |

| H2: ACCO’s Commitment to Innovation | Use of Cutting-Edge Technology in Construction, Implementation of Green Building Standards, Digitalization in Project Management |

| H2: Key Projects Shaping Faisalabad’s Industry | Landmark Industrial Developments (Textile Factories, Power Plants, Industrial Parks), How These Projects Re-defined the City’s Landscape |

| H2: Advanced Construction Techniques | ACCO’s Utilization of Modern Building Materials, Prefabricated Structures, Lean Construction, and Automation |

| H2: Sustainable Building Practices | ACCO’s Emphasis on Eco-Friendly Designs, Sustainable Sourcing of Materials, Reducing Carbon Footprint in Faisalabad’s Industry |

| H2: Infrastructure Development | ACCO’s Role in Developing Critical Infrastructure (Roads, Bridges, Utilities), Impact on Transport and Trade |

| H2: Impact on the Local Economy | Job Creation, Skill Development Initiatives, Promoting Local Suppliers and Industries |

| H2: Modern Industrial Parks | How ACCO Designed and Built Modern Industrial Parks, Facilitating Growth in Key Sectors (Textile, Agriculture, Energy) |

| H2: Industrial Automation and Smart Facilities | ACCO’s Focus on Smart Manufacturing Facilities, Use of IoT in Factories, Enhancing Efficiency through Automation |

| H2: Collaborations with Global Partners | Partnerships with International Construction Firms, Introduction of Global Best Practices in Faisalabad’s Construction Sector |

| H2: Addressing Urbanization Challenges | How ACCO Balanced Industrial Growth with Urban Development, Tackling Population Growth and Housing Issues in Faisalabad |

| H2: Future of Industrial Construction in Faisalabad | ACCO’s Long-Term Vision for the City, Upcoming Projects, Pushing Boundaries with Smart Cities and Sustainable Industrial Growth |

| H2: Testimonials and Success Stories | Insights from Industry Leaders, Case Studies of Businesses that Benefited from ACCO’s Developments |

| H2: Challenges Faced and Overcome by ACCO | Key Obstacles in Modernizing Faisalabad’s Industrial Sector, Solutions Implemented by ACCO to Tackle Them |

| H2: Conclusion | ACCO’s Lasting Legacy in Faisalabad’s Industrial Growth and Its Broader Impact on Pakistan’s Economic Landscape |

| H2: FAQs | Six Frequently Asked Questions About ACCO’s Role and Impact on Faisalabad’s Industrial Transformation |

How ACCO Transformed Faisalabad’s Industrial Landscape with Cutting-Edge Construction

Introduction

Faisalabad, Pakistan’s industrial powerhouse, is renowned for its vast textile industry and bustling economic activity. Historically, the city has been at the forefront of the country’s industrial revolution, primarily due to its central location and access to raw materials. However, the city’s infrastructure and industrial facilities faced significant challenges in accommodating rapid growth and meeting modern standards. This is where ACCO (Allied Construction Company) stepped in, reshaping Faisalabad’s industrial landscape with its innovative and state-of-the-art construction techniques.

This article will dive deep into how ACCO has revolutionized Faisalabad’s industrial sector, its influence on the local economy, and its future ambitions.

Faisalabad’s Industrial Background

Before ACCO’s intervention, Faisalabad was already known as the “Manchester of Pakistan,” famous for its textile industry. The city’s growth was propelled by its strong agricultural roots and a burgeoning workforce ready to engage in industrial activities. However, this rapid expansion brought its own set of challenges. Outdated infrastructure, inefficient facilities, and lack of modern industrial spaces made it difficult for businesses to thrive.

Despite these challenges, Faisalabad’s importance as an industrial hub remained undisputed. The local government recognized the need for modernization but lacked the expertise to implement significant change. This is where ACCO’s expertise became crucial.

The Rise of ACCO in Pakistan

ACCO, founded with the vision of revolutionizing Pakistan’s construction sector, made its mark by introducing advanced building techniques and a strong commitment to quality. Initially involved in commercial and residential construction, ACCO soon expanded into industrial projects due to the growing demand for modern facilities in cities like Faisalabad.

Their entry into the industrial sector began with small-scale projects, but their reputation for delivering high-quality construction on time quickly earned them larger contracts. ACCO’s innovative approach and use of cutting-edge technology enabled it to become a driving force behind Faisalabad’s transformation into a modern industrial hub.

ACCO’s Commitment to Innovation

One of the main reasons ACCO succeeded in transforming Faisalabad’s industrial landscape is its focus on innovation. ACCO has introduced numerous technological advancements in the construction sector, including:

- 3D Modeling and BIM (Building Information Modeling): ACCO uses 3D modeling and BIM technology to plan and execute projects with precision, reducing errors and streamlining construction processes.

- Prefabrication Techniques: By utilizing prefabricated structures, ACCO has reduced construction time and costs while improving quality control.

- Green Building Initiatives: ACCO is committed to sustainability, integrating eco-friendly materials and energy-efficient designs into their projects.

These cutting-edge techniques helped ACCO develop efficient and futuristic industrial facilities, which significantly enhanced the productivity of Faisalabad’s manufacturing sector.

Key Projects Shaping Faisalabad’s Industry

ACCO has been involved in numerous landmark projects that have had a lasting impact on Faisalabad’s industrial growth. Some of these include:

- Textile Factories: ACCO built modern textile factories equipped with advanced machinery and automation systems, helping Faisalabad maintain its dominance in the textile sector.

- Power Plants: ACCO’s involvement in constructing energy-efficient power plants has helped alleviate the region’s electricity shortages, ensuring uninterrupted operations for industries.

- Industrial Parks: By constructing state-of-the-art industrial parks, ACCO has created spaces that foster business growth and encourage foreign investment.

Each of these projects has played a crucial role in reshaping Faisalabad’s industrial landscape.

Advanced Construction Techniques

ACCO’s use of advanced construction techniques has set new standards in the industry. The company is known for implementing:

- Lean Construction: ACCO’s lean construction approach focuses on minimizing waste and maximizing value for clients, ensuring projects are completed efficiently.

- Automation and Robotics: ACCO has integrated automation into its construction processes, using robotic systems for tasks such as material handling and inspection, leading to faster and more accurate construction.

By adopting these techniques, ACCO has been able to construct high-quality industrial facilities that meet global standards.

Sustainable Building Practices

Sustainability is at the heart of ACCO’s construction philosophy. The company has been a pioneer in implementing green building practices in Faisalabad’s industrial projects. Some of the initiatives include:

- Sustainable Materials: ACCO prioritizes the use of locally sourced and environmentally friendly materials in its construction projects.

- Energy-Efficient Designs: ACCO integrates renewable energy sources, such as solar panels, into their buildings, reducing the carbon footprint of industrial facilities.

These sustainable practices not only benefit the environment but also reduce long-term operational costs for businesses.

Infrastructure Development

In addition to industrial facilities, ACCO has played a vital role in the development of critical infrastructure in Faisalabad. This includes the construction of:

- Road Networks: ACCO has been involved in constructing road networks that connect industrial zones with the rest of the city, improving logistics and reducing transportation costs for businesses.

- Bridges and Utilities: The company has also contributed to the construction of bridges and utility networks, further enhancing Faisalabad’s infrastructure.

This infrastructure development has been instrumental in improving the efficiency of industrial operations and boosting the city’s economic growth.

Impact on the Local Economy

ACCO’s projects have had a profound impact on Faisalabad’s local economy. The construction of new industrial facilities has led to the creation of thousands of jobs, both during the construction phase and after the facilities become operational. Moreover, ACCO has focused on training local workers and developing their skills, which has contributed to the growth of a skilled labor force in the region.

Additionally, ACCO’s preference for local suppliers has had a positive ripple effect on the region’s economy, promoting the growth of small and medium-sized enterprises (SMEs) in Faisalabad.

Modern Industrial Parks

One of ACCO’s most significant contributions to Faisalabad’s industrial landscape has been the development of modern industrial parks. These parks are designed to accommodate a variety of industries, including textiles, agriculture, and energy. By providing world-class infrastructure and facilities, these parks have attracted both domestic and international investors, further fueling the city’s economic growth.

Industrial Automation and Smart Facilities

In line with global trends, ACCO has focused on building smart manufacturing facilities that integrate industrial automation and IoT (Internet of Things) technology. These facilities allow businesses to monitor and control their production processes remotely, improving efficiency

You said:

ChatGPT said:

Get Lifetime Access to My Prompts Library: https://bit.ly/Lifetime_Access

Comprehensive Outline: From Blueprint to Reality: A Day in the Life at ACCO Industrial Construction Company

| Main Topics | Subtopics |

|---|---|

| H1: Introduction | Overview of ACCO Industrial Construction Company, Its Role in Transforming Pakistan’s Industrial Landscape |

| H2: The Planning Stage: Blueprints and Beyond | Collaborative Design Process, Use of Digital Tools Like BIM (Building Information Modeling), Coordination with Clients and Stakeholders |

| H2: Morning Briefings and Team Coordination | Daily Kickoff Meetings, Project Managers and Engineers Aligning on Priorities, Delegating Tasks to Various Teams |

| H2: Site Preparations and Safety Protocols | Ensuring Compliance with Safety Standards, Pre-Construction Site Inspections, Worker Safety Training, PPE Implementation |

| H2: Engineering Innovations in the Field | Integration of Advanced Engineering Techniques, Use of Prefabrication, Structural Analysis for Stability and Safety |

| H2: The Role of Technology in ACCO’s Daily Workflow | Use of Drones for Site Surveys, Robotics for Construction Efficiency, Software for Real-Time Tracking and Updates |

| H2: Building Materials and Logistics Management | Sourcing of Sustainable Materials, Coordinating Material Deliveries, Managing Logistics for Large-Scale Projects |

| H2: On-Site Challenges and Problem-Solving | Real-Time Issue Resolution, Handling Unforeseen Construction Obstacles, Maintaining Project Timelines |

| H2: Collaboration Between Departments | Communication Between Design, Engineering, Procurement, and Construction Teams, How Departments Work Together to Ensure Seamless Operations |

| H2: Afternoon Workflow: Progress Monitoring | How ACCO Teams Track and Report Daily Progress, Site Visits by Project Managers, Adjusting Plans According to On-Site Developments |

| H2: Ensuring Quality Control | Quality Inspections, Meeting Industry Standards, Documentation of Compliance with Client Specifications |

| H2: Workforce Management and Development | Coordinating with Contractors and Skilled Workers, Training Initiatives, Ensuring Efficient Workflow on Site |

| H2: Health, Safety, and Environment (HSE) | The Importance of Health and Safety, ACCO’s Safety Training Programs, Ensuring Environmentally Conscious Construction |

| H2: Evening Wrap-Up and Reporting | End-of-Day Meetings, Reporting on Achievements, Logging Issues for the Next Day, Managing Project Documentation |

| H2: Real-World Example: A Case Study | A Walkthrough of One of ACCO’s Recent Industrial Projects, Highlighting Challenges and Achievements Throughout the Day |

| H2: The Bigger Picture: How Each Day Fits into ACCO’s Vision | How Day-to-Day Operations Support ACCO’s Long-Term Goals, Balancing Project Deadlines with Innovation and Sustainability |

| H2: Conclusion | Recap of ACCO’s Commitment to Efficiency, Innovation, and Quality in Industrial Construction |

| H2: FAQs | Frequently Asked Questions About ACCO’s Operations and Daily Workflow |

From Blueprint to Reality: A Day in the Life at ACCO Industrial Construction Company

Introduction

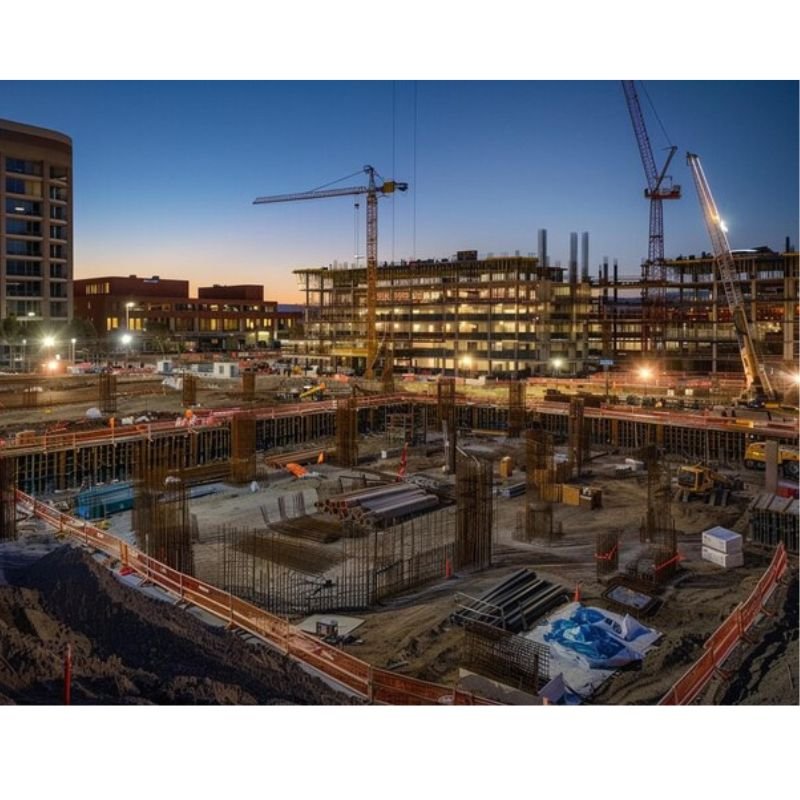

ACCO Industrial Construction Company, one of the leading forces in shaping Pakistan’s industrial infrastructure, has become synonymous with innovation, sustainability, and efficiency. From massive factories and power plants to cutting-edge industrial parks, ACCO has consistently delivered on ambitious projects. But what happens on a typical day at ACCO? This article provides an inside look into the daily operations, showcasing the dynamic workflow, from blueprint to reality, and how ACCO’s teams bring industrial projects to life.

The Planning Stage: Blueprints and Beyond

Every day at ACCO begins long before any on-site work commences. The heart of any construction project lies in the blueprint—meticulously crafted plans that guide every step of the process. Using cutting-edge tools like Building Information Modeling (BIM), ACCO’s architects and engineers collaborate to design industrial facilities with precision.

During this phase, the team works closely with clients and stakeholders to align the project’s goals, ensuring that everything from the layout to sustainability features meets the client’s needs. This planning stage sets the foundation for the entire project, ensuring that once construction begins, every step is executed flawlessly.

Morning Briefings and Team Coordination

As dawn breaks, ACCO’s construction sites buzz with activity. The first order of business is the daily kickoff meeting. Project managers, engineers, site supervisors, and team leaders come together to discuss the day’s objectives. These briefings are critical to the smooth functioning of the construction process, ensuring that everyone is aligned on priorities.

During these meetings, tasks are delegated, and key milestones are reviewed. Communication is key, and each team member understands their role in moving the project forward, whether it’s overseeing material deliveries, handling technical tasks, or coordinating safety protocols.

Site Preparations and Safety Protocols

Safety is paramount at ACCO. Before any construction work begins, the site is prepared according to strict safety standards. Pre-construction site inspections are conducted to assess potential hazards, and safety measures are put in place. ACCO ensures that all workers are equipped with the necessary Personal Protective Equipment (PPE), such as helmets, gloves, and harnesses.

Additionally, workers undergo safety briefings, where they are trained on handling equipment and following safety protocols. At ACCO, there’s a firm commitment to adhering to both local and international safety regulations, ensuring that projects progress without compromising the well-being of the workforce.

Engineering Innovations in the Field

ACCO prides itself on its integration of advanced engineering techniques that bring efficiency to the construction process. Prefabrication, for example, is a game-changer in industrial construction. By building certain components off-site, ACCO reduces time and waste, ensuring that everything fits perfectly once it’s assembled on-site.

Structural analysis, done in real-time, ensures that the buildings meet safety and durability standards. This combination of high-tech engineering and traditional construction know-how is what allows ACCO to deliver projects that stand the test of time.

The Role of Technology in ACCO’s Daily Workflow

Technology is a major part of ACCO’s daily operations. Drones are regularly deployed to survey construction sites, providing aerial views and real-time data that help project managers monitor progress. These drone surveys provide high-precision measurements that can be used for quality control and to detect any discrepancies from the original plan.

Real-time tracking software is also used to monitor the progress of the project. These tools allow ACCO teams to stay on top of each phase of construction, making adjustments as needed and ensuring that deadlines are met.

Building Materials and Logistics Management

Managing building materials is one of the most critical components of industrial construction. ACCO’s procurement team ensures that high-quality, sustainable materials are sourced, often working with local suppliers to reduce costs and support the local economy.

Logistics management is equally important. Coordinating the delivery of materials to the site at the right time ensures that the project progresses smoothly without delays. ACCO’s commitment to sustainability also plays a role here, as the company strives to minimize its carbon footprint by optimizing transportation routes and reducing waste.

On-Site Challenges and Problem-Solving

No day at a construction site is without its challenges. Whether it’s a delay in material delivery, unexpected weather conditions, or a structural issue that needs to be addressed, ACCO’s teams are equipped to handle real-time problem-solving. Engineers and site managers work closely to quickly assess and resolve issues, ensuring that the project stays on track without compromising quality.

ACCO’s culture emphasizes flexibility and quick decision-making, so when problems arise, solutions are implemented swiftly, ensuring minimal disruption to the construction schedule.

Collaboration Between Departments

One of ACCO’s strengths lies in its seamless interdepartmental collaboration. The design, engineering, procurement, and construction teams are in constant communication, ensuring that every detail aligns with the project’s overall objectives. This collaborative spirit ensures that each department is aware of the project’s current status and can make necessary adjustments in real-time, preventing costly mistakes and miscommunication.

Afternoon Workflow: Progress Monitoring

By the afternoon, the focus shifts to monitoring the progress made during the day. ACCO’s project managers and supervisors conduct site visits, checking to ensure that the work is proceeding according to the plan. Progress is tracked against daily and weekly milestones, and any deviations are quickly noted.

This is also the time for additional coordination with subcontractors, material suppliers, and any specialized teams working on different aspects of the project.

Ensuring Quality Control

Quality control is a crucial part of the construction process at ACCO. Throughout the day, ACCO’s quality assurance teams perform inspections to ensure that all work meets industry standards and client specifications. Any discrepancies are addressed immediately, ensuring that the final product is of the highest possible quality.

The company’s emphasis on delivering world-class construction means that cutting corners is never an option. Rigorous quality checks are a regular part of the daily routine to ensure compliance with both local and international construction standards.

Workforce Management and Development

ACCO is dedicated to not only managing its workforce efficiently but also developing the skills of its workers. The company regularly conducts training sessions to ensure that workers are up-to-date with the latest techniques and technologies in industrial construction. This investment in the workforce ensures that employees are highly skilled and motivated, which, in turn, results in better project outcomes.

Health, Safety, and Environment (HSE)

ACCO takes pride in its commitment to Health, Safety, and Environment (HSE) standards. Throughout the day, safety officers conduct inspections to ensure that all safety protocols are followed, from the use of PPE to proper machinery handling. ACCO also integrates environmentally conscious practices into its operations, minimizing waste and reducing environmental impact through sustainable construction techniques.

Evening Wrap-Up and Reporting

As the day winds down, the teams gather for an evening wrap-up meeting. During this session, the day’s progress is reviewed, any issues are logged for follow-up, and plans for the next day are discussed. Daily reporting is crucial for maintaining a clear record of the project’s development and for ensuring transparency with clients.

The end-of-day reporting also helps in aligning future tasks and identifying areas that require extra attention in the coming days.

Real-World Example: A Case Study

Take, for instance, ACCO’s recent development of a textile manufacturing plant in Faisalabad. On a typical day, the project began with morning briefings, where safety protocols were reviewed, and teams were assigned their tasks for the day. Site preparations took place, and prefabricated components were installed with precision. Challenges, such as an unexpected delay in material delivery, were handled through prompt adjustments in the schedule. By the evening, the site was inspected, and daily progress was recorded, keeping the project on track.

The Bigger Picture: How Each Day Fits into ACCO’s Vision

Every day at ACCO is a step toward realizing the company’s broader vision of transforming Pakistan’s industrial landscape. While daily tasks focus on meeting short-term goals and deadlines, ACCO always keeps an eye on long-term objectives like sustainability, innovation, and client satisfaction. This approach ensures that each project contributes to the company’s overarching goal of building a better, more industrialized future for Pakistan.

Conclusion

A day at ACCO Industrial Construction Company is a testament to the company’s dedication to excellence, innovation, and safety. From the blueprint stage to the final product, every step of the process is meticulously planned and executed, with a focus on collaboration, problem-solving, and quality. By adhering to these values, ACCO has cemented its reputation as a leader in industrial construction, playing a pivotal role in shaping the future of Pakistan’s industrial infrastructure.

FAQs

What is the role of technology in ACCO’s construction process?

ACCO integrates advanced technology, such as drones, BIM, and real-time tracking software, to ensure precision, efficiency, and quality in its construction projects.How does ACCO ensure the safety of its workers?

ACCO implements strict safety protocols, conducts regular safety training, and provides personal protective equipment (PPE) to ensure a safe working environment.What is prefabrication, and how does ACCO use it?

Prefabrication involves constructing components off-site and assembling them on-site. ACCO uses this method to speed up the construction process and ensure high-quality results.How does ACCO handle construction challenges?

ACCO’s teams are trained to handle on-site challenges through real-time problem-solving, ensuring that the project stays on track without compromising quality.What are ACCO’s sustainability practices?

ACCO uses sustainable materials, optimizes logistics to reduce carbon emissions, and integrates energy-efficient designs into its projects.How does ACCO maintain quality control?

ACCO conducts regular quality inspections to ensure that all work meets client specifications and complies with industry standards.

From Blueprint to Reality: A Day in the Life at ACCO Industrial Construction Company

From the moment the sun rises over the horizon until the last beam of light fades into dusk, the world of construction hums with energy. But behind every massive industrial facility or precision-built factory lies an entire day of coordinated efforts by professionals at companies like ACCO Industrial Construction. Industrial construction is a field driven by the need for precision, efficiency, and collaboration. ACCO Industrial Construction, a leader in this sector, ensures that every blueprint transforms into a tangible, operational structure. Let’s take an in-depth look at what a day at ACCO Industrial Construction Company really entails, from the initial planning phase to final completion.

Introduction to ACCO Industrial Construction

The world of industrial construction is one of complexity and scale, and ACCO Industrial Construction has earned its reputation as a powerhouse in this domain. Specializing in the development of large-scale industrial projects, ACCO handles everything from manufacturing plants to refineries, leveraging decades of experience and innovation.

At the core of ACCO’s success is its ability to turn vision into reality—whether the project calls for the construction of energy-efficient warehouses or state-of-the-art facilities tailored for precision manufacturing. This transformation process is driven by a highly structured and coordinated effort that begins each day with detailed planning and ends with real progress on the ground.

The Pre-Dawn Start: Planning and Briefing

The typical day at ACCO Industrial Construction begins before the sun is even up. By the time the project site is bathed in the first light of day, critical planning and preparations have already been underway. The project management team arrives early to review the day’s objectives, assess any potential challenges, and ensure that all team members are aligned.

During this stage, blueprints and designs are revisited to confirm that the previous day’s work meets the high standards of industrial construction. These planning sessions also give the team a chance to discuss any modifications or adjustments that need to be made, especially if unforeseen circumstances—such as weather conditions or material delays—have come into play.

Every department within ACCO—whether it’s engineering, architecture, or logistics—comes together in these early hours to ensure that the day’s efforts are efficient and well-coordinated. These morning briefings are the foundation of the seamless progress that ACCO is known for.

The Role of Technology in ACCO’s Day-to-Day Operations

One key element that sets ACCO Industrial Construction apart from its competitors is its innovative use of technology. Each day, advanced project management software allows the team to track the progress of ongoing projects, manage resource allocation, and ensure that every task stays on schedule. These systems help keep the entire team informed, from project managers to on-site laborers, minimizing miscommunication and optimizing efficiency.

The use of Building Information Modeling (BIM) is another cutting-edge technique that ACCO leverages to stay ahead in industrial construction. With BIM, the construction team can create digital representations of buildings, allowing for more detailed planning and real-time adjustments. Throughout the day, engineers and architects may refer to these digital models, ensuring every aspect of the blueprint is followed to the letter.

From Blueprint to Reality: Engineering and Design

As the day progresses, one of the most crucial tasks involves translating the blueprint—the design on paper—into an actual, physical structure. This stage demands close collaboration between engineers, architects, and construction workers.

At ACCO, the team makes sure every dimension, angle, and specification matches the design laid out in the project’s blueprint. For industrial construction, this precision is particularly critical. Whether it’s aligning heavy machinery foundations, ensuring safety protocols are followed, or constructing specialized facilities that must meet stringent environmental and operational standards, there is little room for error.

The engineering department often conducts on-site inspections to ensure every step aligns with the project’s design. If adjustments need to be made, this process involves rapid communication and quick but thorough problem-solving.

On-Site Teamwork and Execution

By mid-morning, the construction site at ACCO is a hive of activity. Teams are divided based on specialized tasks—some may be working on the foundational structures of the building, while others focus on electrical systems, plumbing, or structural reinforcements. In industrial construction, different teams are constantly in motion, yet working in close coordination to ensure safety and quality control.

Site supervisors play an integral role in making sure the work meets ACCO’s rigorous standards. They oversee operations, check that safety protocols are strictly adhered to, and ensure each phase is completed before moving on to the next. This fluid but well-coordinated process ensures that projects are completed efficiently without sacrificing quality.

Managing Challenges on an Industrial Construction Site

Challenges on an industrial construction site are inevitable. Whether it’s unpredictable weather, supply chain delays, or unforeseen structural issues, ACCO’s team is equipped to respond swiftly and effectively. Each day, there may be obstacles that threaten to slow down or complicate the project. However, ACCO’s experienced team is always prepared to find solutions.

For example, if a delivery of materials is delayed, the team can rearrange tasks to keep productivity high without disrupting the overall timeline. Engineers and architects may work closely together to identify alternative methods or materials that can be used without compromising the integrity or safety of the structure.

Communication is key in these moments. ACCO’s project managers rely heavily on real-time updates from all teams to make informed decisions and avoid delays. Every day on an industrial construction site requires quick thinking, and ACCO’s team excels at keeping the project moving forward despite any hurdles.

Safety First: Prioritizing Worker and Site Safety

Safety is a non-negotiable aspect of ACCO Industrial Construction’s daily operations. As one of the cornerstones of their success, strict safety protocols are enforced to protect both workers and the integrity of the project. Each day begins with a safety briefing, during which teams are reminded of site-specific hazards, the importance of personal protective equipment (PPE), and the latest updates to safety regulations.

The safety officer conducts regular inspections throughout the day, ensuring that everyone is complying with the set standards. In industrial construction, where heavy machinery, hazardous materials, and complex equipment are part of the daily routine, maintaining a safety-first culture is essential.

The Impact of ACCO Industrial Construction on the Economy

As an industry leader, ACCO Industrial Construction is more than just a company building structures; it’s a driver of economic growth. Every day, the company is responsible for providing jobs for hundreds of workers—from skilled laborers to engineers, project managers, and administrative staff. Additionally, the projects completed by ACCO often play a critical role in supporting other industries, such as manufacturing, energy, and logistics.

ACCO’s industrial projects are designed to meet the needs of modern business operations, providing cutting-edge facilities that improve operational efficiency for their clients. This, in turn, boosts economic productivity in the broader market.

Sustainable Construction Practices at ACCO

One trend that has become increasingly prevalent at ACCO is the focus on sustainability. Every day, more attention is paid to how materials are sourced, how energy is used on-site, and how waste is managed during the construction process. ACCO makes an effort to adopt eco-friendly practices, utilizing energy-efficient machinery and promoting the use of sustainable building materials.

As global awareness of environmental impact grows, ACCO Industrial Construction takes a proactive stance on reducing its carbon footprint, ensuring that every project is as eco-friendly as possible without compromising on quality.

FAQs

How does ACCO Industrial Construction manage large-scale projects?

ACCO uses advanced project management software and a highly coordinated team structure to ensure that every task is completed on time and meets the high standards of industrial construction.

What types of buildings does ACCO specialize in?

ACCO specializes in industrial buildings, including manufacturing plants, warehouses, refineries, and other large-scale facilities.

How does ACCO handle challenges during construction?

ACCO’s experienced project managers and engineers work collaboratively to address challenges like material delays, weather disruptions, and design changes quickly and effectively.

What role does technology play in ACCO’s operations?

ACCO integrates technology such as Building Information Modeling (BIM) and real-time project management systems to ensure that each project is completed efficiently and with precision.

What safety measures does ACCO implement?

ACCO prioritizes safety with daily briefings, strict PPE regulations, and regular inspections by on-site safety officers to ensure compliance with industry standards.

How does ACCO contribute to sustainability?

ACCO focuses on sustainable practices, using eco-friendly materials, energy-efficient equipment, and waste reduction strategies throughout the construction process.

Conclusion

A day in the life of ACCO Industrial Construction Company is a dynamic, meticulously coordinated operation that showcases the expertise, collaboration, and innovation needed to transform blueprints into tangible structures. From the first light of day to the final quality check, ACCO continues to set the standard for industrial construction, delivering world-class projects that fuel the economy while adhering to the highest levels of safety and sustainability. Whether constructing a cutting-edge manufacturing plant or building energy-efficient industrial spaces, ACCO’s commitment to excellence ensures that each project not only meets but exceeds expectations.

Inbound links: