Factory & Industrial Unit Construction Services Pakistan

Factory & Industrial Unit Construction Services Pakistan

Outline of the Article

H1: Introduction to Factory & Industrial Unit Construction in Pakistan

-

Importance of Industrial Development

-

Role of Construction Companies in Industrial Growth

H2: Understanding Industrial Unit Construction

-

What Is an Industrial Unit?

-

Differences Between Factories and Industrial Units

H2: Why Pakistan is Seeing a Surge in Industrial Construction

-

Government Initiatives

-

CPEC & Special Economic Zones (SEZs)

-

Increased Local & Foreign Investment

H2: Key Elements of Factory & Industrial Construction

-

Site Selection & Feasibility

-

Design & Engineering

-

Structural Integrity & Compliance

-

Electrical, Plumbing, and HVAC Considerations

H2: Types of Industrial Units Built in Pakistan

-

Textile Factories

-

Food Processing Units

-

Pharmaceutical Manufacturing Plants

-

Logistics & Warehousing Units

H2: Top Challenges in Factory Construction in Pakistan

-

Regulatory Hurdles

-

Land Acquisition Issues

-

Skilled Labor Shortage

-

Utility and Infrastructure Limitations

H2: How ACCO Construction Leads the Industrial Construction Sector

-

Overview of ACCO Engineering & Construction

-

Turnkey Project Handling

-

Use of Modern Technology and Materials

H2: Project Lifecycle of an Industrial Construction Project

-

Initial Consultation

-

Planning and Budgeting

-

Design & Approvals

-

Execution & Quality Control

-

Handover and Maintenance

H2: Legal and Environmental Compliance

-

Building Codes in Pakistan

-

Environmental Impact Assessments (EIA)

-

Fire Safety Standards

H2: Benefits of Hiring Professional Industrial Construction Services

-

Cost Efficiency

-

Faster Completion

-

Adherence to International Standards

H2: Technologies Used in Modern Industrial Construction

-

BIM (Building Information Modeling)

-

Prefabrication and Modular Buildings

-

Smart Factory Features

H2: Budgeting and Cost Estimation for Industrial Projects

-

Cost Factors

-

Hidden Expenses

-

Financing Options

H2: Future Trends in Factory Construction in Pakistan

-

Green Construction

-

Energy-Efficient Industrial Buildings

-

Automation & AI Integration

H2: Tips for Selecting the Right Construction Partner

-

Experience & Portfolio

-

Client Reviews & Case Studies

-

Safety and Quality Control Measures

H2: Why ACCO Should Be Your First Choice

-

Industry Experience

-

Nationwide Operations

-

Contact Information

Article:

Introduction to Factory & Industrial Unit Construction in Pakistan

Pakistan’s industrial sector is rapidly evolving. With new policies encouraging investment and growth, the demand for modern factories and industrial units has skyrocketed. But constructing a reliable, efficient, and regulation-compliant industrial unit isn’t as simple as putting bricks together—it’s a complex, multi-layered process that requires deep expertise and planning.

Understanding Industrial Unit Construction

So, what exactly is an industrial unit? It can be anything from a textile manufacturing plant to a high-tech packaging facility. While the term “factory” is often used interchangeably, industrial units can include a broader range of operations like warehousing, research labs, and assembly units.

Each of these has different requirements in terms of structural layout, utility setups, and environmental compliance. That’s where professional industrial construction services come into play.

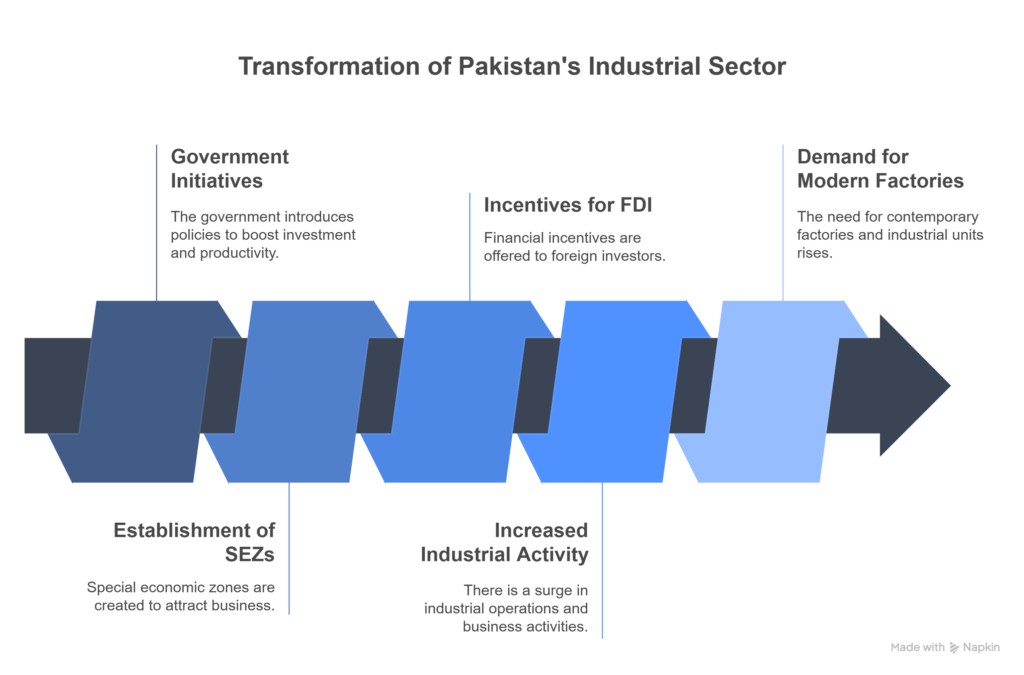

Why Pakistan is Seeing a Surge in Industrial Construction

Pakistan is going through a major industrial boom—and it’s not by accident.

Government Initiatives

With tax incentives and relaxed import policies, the government is actively pushing for more industrialization. Schemes like the “Make in Pakistan” initiative aim to boost local production and reduce import dependency.

CPEC & Special Economic Zones (SEZs)

The China-Pakistan Economic Corridor (CPEC) has been a game changer. The development of Special Economic Zones (SEZs) has attracted both local and international investors, leading to a boom in factory construction.

Increased Local & Foreign Investment

From textile magnates in Faisalabad to international investors in Gwadar, industrial construction is happening across the country.

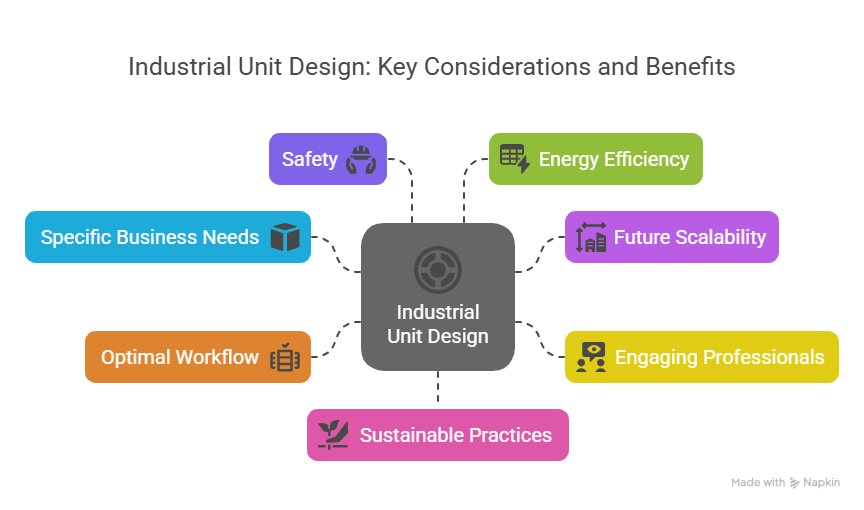

Key Elements of Factory & Industrial Construction

There’s a lot more to building an industrial unit than pouring concrete and raising walls. Here’s what really goes into it:

Site Selection & Feasibility

Choosing the right site is critical. Factors like proximity to transport, availability of utilities, and environmental impact play a big role.

Design & Engineering

Custom design that suits the operation of your factory is key. This includes structural engineering, workflow layout, and expansion possibilities.

Structural Integrity & Compliance

Factories must withstand heavy machinery, vibrations, and sometimes even chemicals. So structural integrity is non-negotiable.

Electrical, Plumbing, and HVAC Considerations

Efficient utility layouts and systems can save you millions in the long run.

Types of Industrial Units Built in Pakistan

Here are a few sectors where industrial construction is booming:

-

Textile Factories: Especially in Lahore, Faisalabad, and Karachi

-

Food Processing Units: For export and local consumption

-

Pharmaceutical Plants: Designed to meet WHO standards

-

Logistics & Warehousing: E-commerce is fueling demand here

Top Challenges in Factory Construction in Pakistan

It’s not always smooth sailing.

Regulatory Hurdles

Getting permits and NOCs can be time-consuming.

Land Acquisition Issues

Zoning and title clearance can delay projects.

Skilled Labor Shortage

High-quality labor is not always readily available, especially in rural or developing areas.

Utility and Infrastructure Limitations

Water, electricity, and gas connections are still a bottleneck in some regions.

How ACCO Construction Leads the Industrial Construction Sector

ACCO Construction isn’t just a name—it’s a promise of quality, commitment, and innovation.

Overview of ACCO Engineering & Construction

With over a decade of experience, ACCO has delivered numerous industrial projects across Pakistan.

Turnkey Project Handling

From design to delivery, ACCO manages everything, so you can focus on running your business.

Use of Modern Technology and Materials

ACCO uses high-quality, sustainable materials and follows global best practices.

Project Lifecycle of an Industrial Construction Project

-

Initial Consultation

-

Planning and Budgeting

-

Design & Approvals

-

Execution & Quality Control

-

Handover and Maintenance

Legal and Environmental Compliance

You can’t skip this part—period.

Building Codes in Pakistan

Every city has different bylaws. Following them is crucial.

Environmental Impact Assessments (EIA)

You must ensure that your unit doesn’t harm the environment.

Fire Safety Standards

Proper fire exits, alarms, and suppression systems are a must.

Benefits of Hiring Professional Industrial Construction Services

Let the pros handle it.

-

Cost-effective

-

On-time delivery

-

Legal compliance

-

Access to better designs and technologies

Technologies Used in Modern Industrial Construction

-

BIM: Allows 3D modeling for precise planning

-

Prefabrication: Speeds up construction time

-

Smart Factory Features: Automation, IoT integration, and more

Budgeting and Cost Estimation for Industrial Projects

Don’t start without a plan.

-

Material Costs

-

Labor

-

Design & Engineering Fees

-

Permits and Taxes

-

Hidden Costs

Future Trends in Factory Construction in Pakistan

-

Green Construction

-

LEED-Certified Buildings

-

Use of Renewable Energy

-

AI-Driven Operations

Tips for Selecting the Right Construction Partner

-

Check previous projects

-

Talk to past clients

-

Ensure transparency in budgeting

-

Ask about post-construction support

Why ACCO Should Be Your First Choice

From idea to execution, ACCO Construction is with you every step of the way. We understand Pakistan’s industrial terrain like no one else.

-

✅ Decades of Experience

-

✅ In-House Architects & Engineers

-

✅ Quality Materials & Timely Delivery

Website: www.acco.com.pk

Email: info@acco.com.pk

Phone: 0322-8000190

Conclusion

Factory and industrial unit construction in Pakistan is not just growing—it’s evolving. Whether you’re a local entrepreneur or an international investor, building a well-designed, compliant, and efficient facility is the key to long-term success. ACCO Construction is here to make that journey smooth, reliable, and profitable.

FAQs

1. How long does it take to build a factory in Pakistan?

It typically takes 6–12 months depending on the size and complexity of the project.

2. What documents are required for factory construction?

Land title, building plan approvals, environmental clearance, and utility permits are commonly required.

3. Is prefabrication used in industrial construction in Pakistan?

Yes, modern companies like ACCO are increasingly using prefabrication for faster project completion.

4. Are industrial buildings eligible for tax benefits?

Yes, under several government schemes, including SEZs and industrial zones.

5. What is the average cost of constructing an industrial unit?

Costs vary but generally range from PKR 1,800 to PKR 4,000 per square foot depending on location and specifications.

Main Building Works

- Planning & Design

- New Build Constructions

- Extensions Of Buildings

- Building Refurbishments

- Ground Works & Foundations

- Concrete Slab Base

- Steel Frame Structures

- Brick & Block Work

- External Cladding

External Building Works

- Demolition/Clearances

- Asbestos Removals

- Drainage & Mains Service Supply

- Fencing & Landscaping

- Car Parks & Access Roads

- Canopies & Stockyards

- Renewable Energy Systems

- Roofing Upgrades

- Roller/Access Doors

Interior Works

- Suspended Ceilings

- Partitioning & Dry Lining

- Specialist Flooring Systems

- Mezzanine Floor Structures

- New Office Areas

- Staff Canteen & Toilet Areas

- Conference/Meeting Rooms

- Power/Data/Telecoms

- Fire Protection/Security Systems

- Energy Saving Lighting

Comprehensive Overview of Building Works

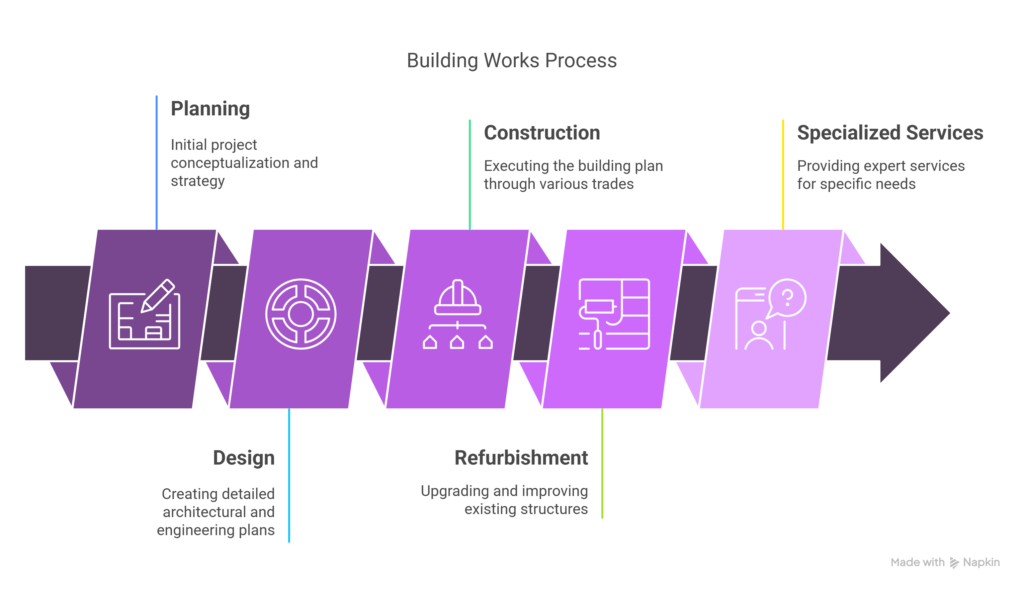

This document provides a detailed overview of various building works, including planning, design, construction, refurbishment, and specialized services. It serves as a guide for stakeholders involved in the construction industry, offering insights into the different aspects of building projects from inception to completion.

Main Building Works

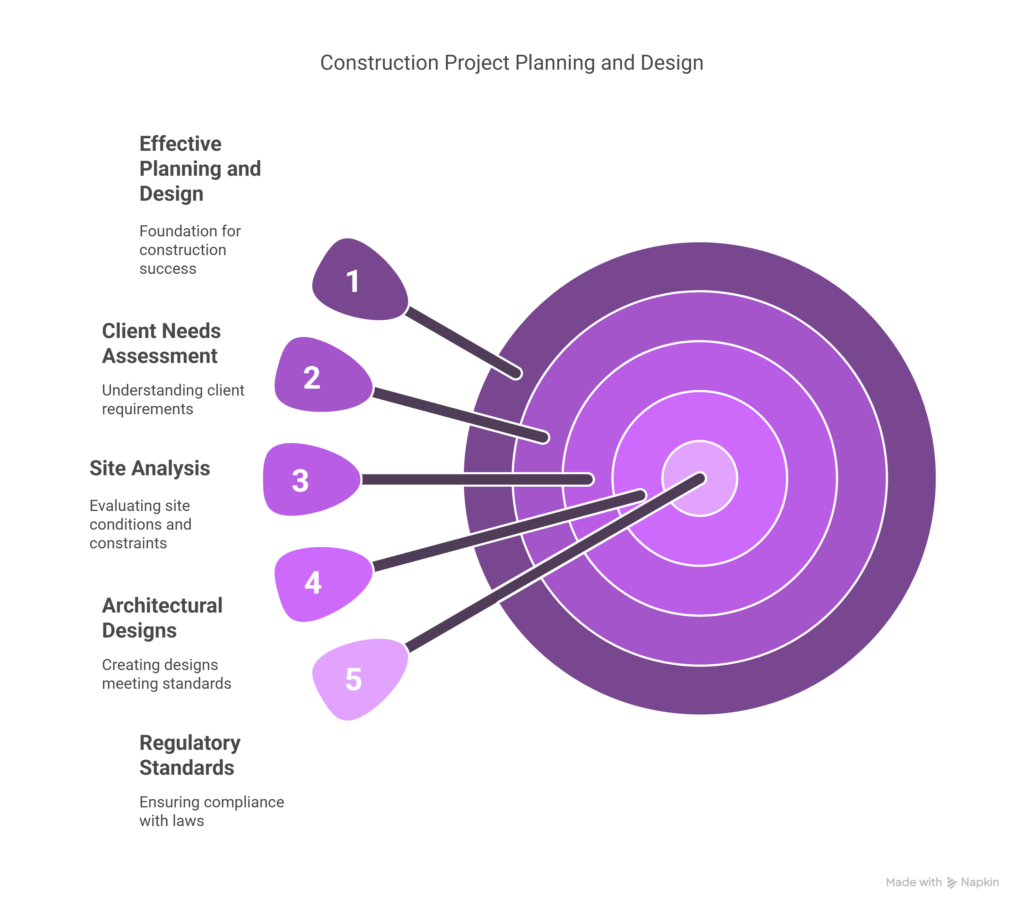

Planning & Design

Effective planning and design are crucial for the success of any construction project. This phase involves assessing the needs of the client, site analysis, and creating architectural designs that meet regulatory standards.

New Build Constructions

New build constructions refer to the process of erecting a completely new structure. This includes residential, commercial, and industrial buildings, requiring careful coordination of various trades and materials.

Extensions Of Buildings

Building extensions involve adding new space to an existing structure. This can enhance functionality and increase property value, requiring careful integration with the existing design.

Building Refurbishments

Refurbishments breathe new life into older buildings, updating them to meet modern standards while preserving their historical value. This may include structural repairs, aesthetic upgrades, and compliance improvements.

Ground Works & Foundations

Ground works lay the foundation for any construction project. This includes excavation, soil stabilization, and the installation of foundational elements that ensure the stability and longevity of the structure.

Concrete Slab Base

A concrete slab base provides a solid foundation for various types of buildings. It is essential for load-bearing structures and requires precise engineering and pouring techniques.

Steel Frame Structures

Steel frame structures offer strength and flexibility, making them ideal for large buildings. This construction method allows for open spaces and is often used in commercial and industrial applications.

Brick & Block Work

Brick and block work is a traditional method of construction that provides durability and aesthetic appeal. It is commonly used for walls, facades, and other structural elements.

External Cladding

External cladding enhances the building’s appearance and provides insulation and weather resistance. Various materials can be used, including wood, metal, and composite materials.

External Building Works

External building works encompass all activities outside the main structure, including landscaping, drainage, and access roads, ensuring the site is functional and visually appealing.

Demolition/Clearances

Demolition and clearances involve safely dismantling existing structures to make way for new construction. This process must adhere to safety regulations and environmental considerations.

Asbestos Removals

Asbestos removals are critical in older buildings to ensure safety and compliance with health regulations. This process requires specialized training and equipment to handle hazardous materials.

Drainage & Mains Service Supply

Effective drainage and mains service supply are essential for any building project, ensuring proper waste management and access to utilities such as water, gas, and electricity.

Fencing & Landscaping

Fencing and landscaping enhance the aesthetic appeal and security of a property. This includes the installation of fences, gates, and the design of outdoor spaces.

Car Parks & Access Roads

Car parks and access roads are vital for functionality, providing safe and convenient access to buildings. Proper planning ensures efficient traffic flow and compliance with regulations.

Canopies & Stockyards

Canopies provide shelter and protection for outdoor areas, while stockyards are essential for agricultural and industrial operations, requiring careful design and construction.

Renewable Energy Systems

Incorporating renewable energy systems, such as solar panels and wind turbines, promotes sustainability and reduces energy costs, aligning with modern environmental standards.

Roofing Upgrades

Roofing upgrades enhance the durability and energy efficiency of a building. This may involve replacing old roofs or adding insulation and weatherproofing materials.

Roller/Access Doors

Roller and access doors provide security and convenience for commercial and industrial buildings. They are designed for high-traffic areas and must meet specific operational requirements.

Interior Works

Suspended Ceilings

Suspended ceilings improve acoustics and aesthetics in interior spaces. They allow for easy access to utilities while providing a clean and modern look.

Partitioning & Dry Lining

Partitioning and dry lining create flexible interior layouts, allowing for the division of spaces without major structural changes. This is essential for adapting to changing needs.

Specialist Flooring Systems

Specialist flooring systems cater to specific requirements, such as durability, safety, and aesthetics. Options include anti-slip surfaces, soundproofing, and eco-friendly materials.

Mezzanine Floor Structures

Mezzanine floor structures maximize vertical space in buildings, providing additional usable area without the need for extensive construction.

New Office Areas

Creating new office areas involves designing functional and comfortable workspaces that promote productivity and collaboration among employees.

Staff Canteen & Toilet Areas

Staff canteens and toilet areas are essential for employee welfare, requiring thoughtful design to ensure comfort and accessibility.

Conference/Meeting Rooms

Conference and meeting rooms are designed for collaboration and communication, equipped with necessary technology and comfortable furnishings.

Power/Data/Telecoms

The installation of power, data, and telecom systems is crucial for modern buildings, ensuring connectivity and functionality for all occupants.

Fire Protection/Security Systems

Fire protection and security systems are vital for the safety of occupants and property. This includes alarms, sprinklers, and surveillance systems.

Energy Saving Lighting

Energy-saving lighting solutions reduce energy consumption and costs while enhancing the overall ambiance of interior spaces.

This document serves as a comprehensive guide to the various aspects of building works, highlighting the importance of each phase in the construction process.