Complete Factory Design and Construction by ACCO

Outline for the Article: “Complete Factory Design and Construction by ACCO”

| Main Headings | Subheadings |

|---|---|

| 1. Introduction to ACCO and Its Expertise in Factory Design and Construction | – Overview of ACCO’s history and reputation – ACCO’s industrial construction portfolio |

| 2. Importance of Factory Design in Modern Manufacturing | – The role of effective design in operational efficiency – Impact on cost management and sustainability |

| 3. Key Considerations in Factory Design | – Space optimization – Flexibility for future expansions – Compliance with safety and environmental standards |

| 4. Phases of Factory Design by ACCO | – Initial consultation and needs assessment – Conceptual design and feasibility analysis |

| 5. ACCO’s Approach to Engineering and Planning | – Civil engineering and infrastructure planning – Mechanical, electrical, and plumbing (MEP) design |

| 6. Sustainability in ACCO’s Factory Designs | – Energy-efficient building materials – Water management systems and waste reduction practices |

| 7. Role of Technology in ACCO’s Factory Construction | – Use of CAD and BIM in design – Automation in construction processes |

| 8. Compliance with International Standards and Regulations | – Safety regulations (OSHA, ISO, etc.) – Environmental standards (LEED, BREEAM certifications) |

| 9. Factory Construction Process: Step-by-Step Guide | – Pre-construction planning – Procurement of materials and equipment – Construction management and scheduling |

| 10. The Role of Project Management in Factory Construction | – ACCO’s project management framework – Risk management and mitigation strategies |

| 11. Equipment Installation and Systems Integration | – Coordinating equipment layout with design – Integration of smart factory systems |

| 12. Post-Construction Services and Maintenance Support | – Final inspection and quality assurance – Ongoing maintenance and service contracts |

| 13. Cost Breakdown and Budgeting for Factory Design and Construction | – Cost of materials, labor, and equipment – Managing project timelines and minimizing overruns |

| 14. Case Studies of ACCO’s Factory Construction Projects | – Success stories from diverse industries – Testimonials and client satisfaction |

| 15. Future Trends in Factory Design and Construction by ACCO | – Smart factories and IoT integration – Modular construction and prefabrication |

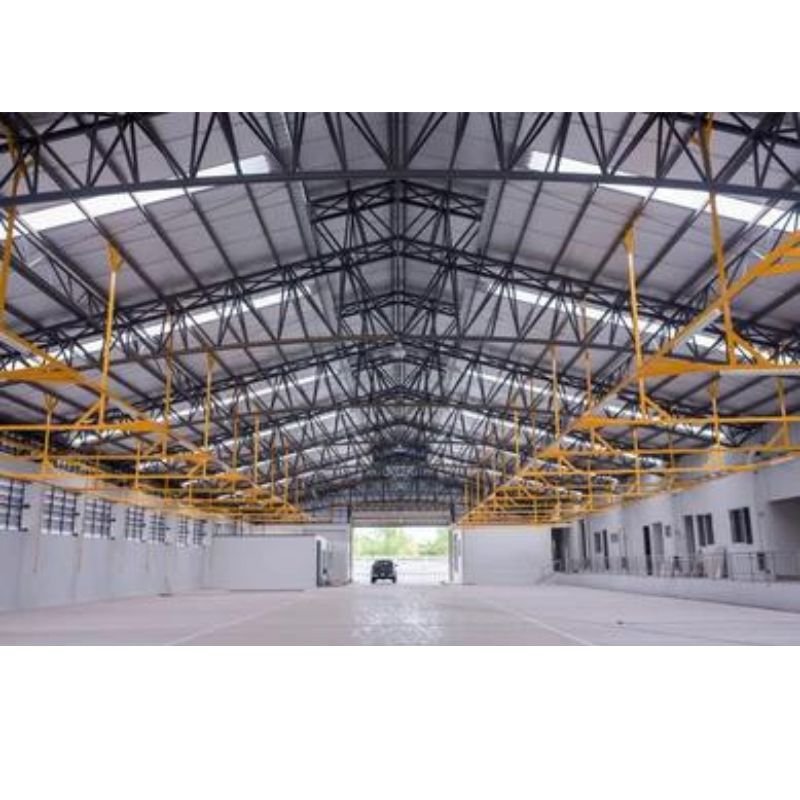

Complete Factory Design and Construction by ACCO

1. Introduction to ACCO and Its Expertise in Factory Design and Construction

ACCO, a leading name in industrial construction, specializes in delivering comprehensive factory design and construction services tailored to meet the evolving needs of modern manufacturing facilities. With decades of experience in large-scale construction projects, ACCO has built a reputation for creating efficient, sustainable, and cost-effective factories across a range of industries, including automotive, electronics, pharmaceuticals, and more. ACCO’s commitment to innovation and excellence ensures that each project is not only completed on time but also exceeds client expectations in terms of quality and functionality.

From initial consultation to the final handover, ACCO’s team of architects, engineers, and construction professionals collaborate closely with clients to ensure their unique requirements are met. Their comprehensive approach ensures that every aspect, from structural integrity to workflow efficiency, is meticulously planned and executed.

2. Importance of Factory Design in Modern Manufacturing

The design of a factory plays a pivotal role in determining its long-term operational efficiency, flexibility, and safety. A well-designed factory not only enhances productivity by optimizing workflow but also reduces operational costs by minimizing waste and energy consumption. Effective design also plays a critical role in employee safety and comfort, which can lead to increased productivity and job satisfaction.

In today’s competitive manufacturing landscape, having a facility that can adapt to new technologies, processes, and expansions is vital. ACCO ensures that factories are designed with future needs in mind, allowing for seamless integration of new equipment, systems, and production lines. Additionally, sustainable design practices, such as energy-efficient lighting and heating systems, not only reduce environmental impact but also lead to long-term cost savings.

3. Key Considerations in Factory Design

When designing a factory, several key factors must be taken into account:

- Space Optimization: Ensuring that the factory layout maximizes the use of available space, whether for production lines, storage, or administrative offices, is critical for efficiency.

- Flexibility for Future Expansions: Factories must be designed with flexibility in mind to accommodate future growth or changes in production needs.

- Compliance with Safety and Environmental Standards: ACCO prioritizes adherence to all relevant local and international regulations, ensuring the safety of both workers and the environment.

4. Phases of Factory Design by ACCO

ACCO follows a structured approach to factory design that ensures all client requirements are met:

- Initial Consultation and Needs Assessment: ACCO’s team conducts a thorough analysis of the client’s needs, including production requirements, budget constraints, and long-term goals.

- Conceptual Design and Feasibility Analysis: A conceptual design is developed, outlining the factory’s basic layout and operational flow. Feasibility studies are conducted to ensure the design is practical and aligns with the client’s vision.

5. ACCO’s Approach to Engineering and Planning

ACCO’s engineering expertise ensures that all aspects of the factory’s design, from civil infrastructure to mechanical, electrical, and plumbing (MEP) systems, are seamlessly integrated. By using advanced engineering tools and methodologies, ACCO creates factories that are not only functional but also durable and efficient.

- Civil Engineering: This includes site preparation, foundation work, and structural integrity planning.

- MEP Design: Mechanical, electrical, and plumbing systems are designed to ensure smooth operation of all factory processes.

6. Sustainability in ACCO’s Factory Designs

Sustainability is at the core of ACCO’s design philosophy. Modern factories are designed with energy efficiency in mind, incorporating renewable energy sources like solar panels, energy-efficient lighting, and HVAC systems. Water conservation systems and waste management protocols are also prioritized to minimize environmental impact.

- Energy-Efficient Materials: ACCO uses sustainable building materials that not only reduce the factory’s carbon footprint but also lower operational costs.

- Water Management Systems: Effective water usage and recycling systems help reduce waste and ensure sustainable operations.

7. Role of Technology in ACCO’s Factory Construction

Technology plays a significant role in both the design and construction phases of a factory. ACCO leverages advanced tools such as Computer-Aided Design (CAD) and Building Information Modeling (BIM) to create accurate, efficient, and cost-effective designs.

- CAD and BIM: These technologies allow for precision in planning, enabling the simulation of factory operations and the identification of potential issues before construction begins.

- Automation in Construction: ACCO incorporates automated systems in the construction process to improve speed, accuracy, and safety.

8. Compliance with International Standards and Regulations

ACCO ensures that all of its factory designs comply with international safety and environmental standards. This includes:

- Safety Regulations: ACCO adheres to OSHA guidelines to ensure the safety of workers and equipment.

- Environmental Certifications: Factories are designed to meet LEED or BREEAM certification standards, ensuring they are environmentally friendly.

9. Factory Construction Process: Step-by-Step Guide

The construction of a factory involves multiple stages, each carefully managed by ACCO’s team of experts:

- Pre-Construction Planning: This phase involves detailed planning and coordination of all necessary resources, including materials, labor, and equipment.

- Procurement: ACCO handles the sourcing of high-quality materials and equipment needed for the project.

- Construction Management: Throughout the construction process, ACCO’s team ensures that the project stays on schedule and within budget.

10. The Role of Project Management in Factory Construction

Effective project management is crucial to the success of any factory construction project. ACCO employs a robust project management framework that includes:

- Risk Management: Identifying and mitigating potential risks to avoid delays or budget overruns.

- Quality Control: Ensuring that all construction work meets the highest standards of quality and safety.

11. Equipment Installation and Systems Integration

Once construction is complete, ACCO assists with the installation and integration of all necessary factory equipment. This includes:

- Equipment Layout: Coordinating the layout of equipment to maximize operational efficiency.

- Smart Factory Systems: Integrating IoT and automation systems to create a smart factory environment.

12. Post-Construction Services and Maintenance Support

ACCO provides comprehensive post-construction services to ensure that the factory continues to operate smoothly. These services include:

- Final Inspection: A thorough inspection is conducted to ensure the factory meets all design and operational specifications.

- Maintenance Contracts: ACCO offers ongoing maintenance and support services to ensure the long-term success of the factory.

13. Cost Breakdown and Budgeting for Factory Design and Construction

ACCO provides transparent cost estimates and detailed budgeting for factory design and construction. Key components include:

- Materials and Equipment Costs: ACCO sources high-quality materials that meet both performance and budgetary requirements.

- Labor Costs: Experienced professionals are employed to ensure the project is completed efficiently and to a high standard.

14. Case Studies of ACCO’s Factory Construction Projects

ACCO has successfully completed numerous factory construction projects across a range of industries. Some notable examples include:

- Automotive Manufacturing Facility: ACCO designed and built a state-of-the-art automotive plant that incorporated advanced robotics and automation systems.

- Pharmaceutical Factory: A pharmaceutical plant designed by ACCO was recognized for its energy-efficient design and adherence to stringent safety standards.

15. Future Trends in Factory Design and Construction by ACCO

As technology continues to evolve, ACCO is at the forefront of adopting new trends in factory design and construction. Key future trends include:

- Smart Factories: Incorporating IoT and AI-driven systems to optimize production processes.

- Modular Construction: Prefabricated factory components that can be assembled quickly, reducing construction time and costs.

Frequently Asked Questions (FAQs)

What services does ACCO provide in factory design and construction?

ACCO offers comprehensive services including design consultation, engineering, construction, and post-construction maintenance, all tailored to meet specific industrial needs.How does ACCO ensure project deadlines are met?

ACCO uses advanced project management techniques, real-time monitoring tools, and risk mitigation strategies to keep projects on track.Is ACCO experienced in designing sustainable factories?

Yes, ACCO prioritizes sustainability by using energy-efficient materials and incorporating renewable energy systems in its designs.Can ACCO handle factory expansion projects?

Absolutely, ACCO designs factories with flexibility in mind, allowing for future expansions or modifications as needed.What industries does ACCO work with?

ACCO has extensive experience across various industries including automotive, pharmaceuticals, electronics, and consumer goods manufacturing.Does ACCO provide maintenance services after construction?

Yes, ACCO offers comprehensive maintenance and support services to ensure the long-term efficiency of the factory.