Introduction to Pre-Engineered Steel Buildings (PEB)

- Definition and Overview of PEB

- Why PEBs Are Gaining Popularity

History of Pre-Engineered Buildings

- Origins of PEB Technology

- Evolution and Adoption Globally

Components of a Pre-Engineered Steel Building

- Primary Frame: Beams and Columns

- Secondary Structural Elements: Purlins, Girts

- Roof and Wall Panels

- Bracing and Connectors

- Accessories: Ventilators, Skylights, etc.

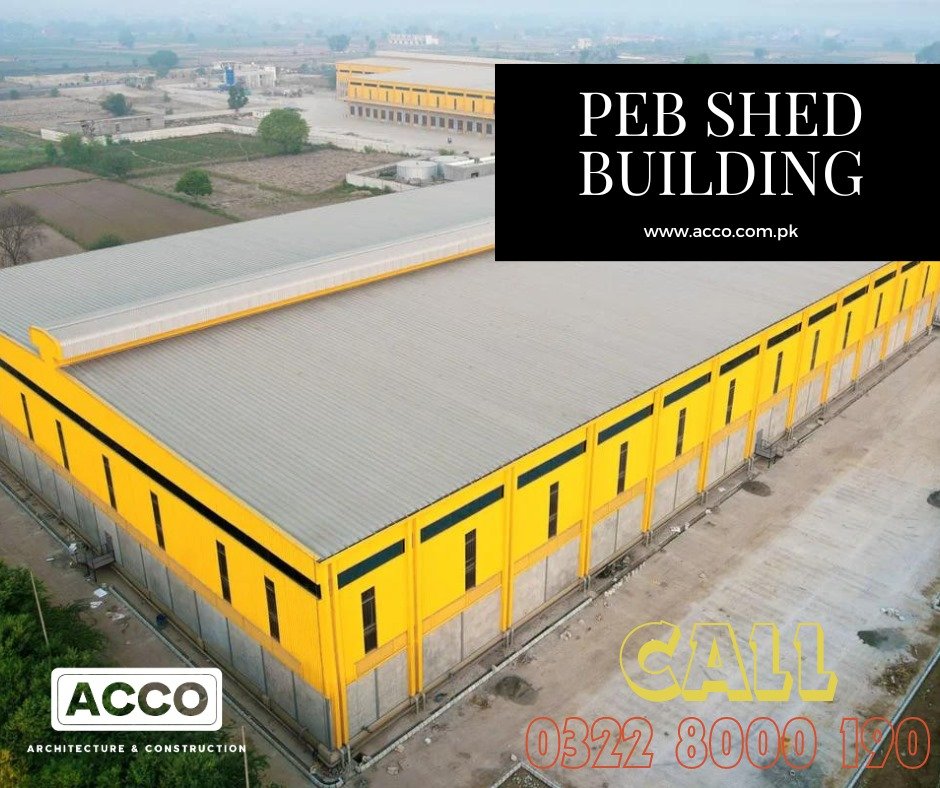

The ACCO Brand: A Brief Introduction

- Overview of ACCO’s History and Expertise

- ACCO’s Role in the PEB Industry

Advantages of ACCO Pre-Engineered Steel Buildings

- Cost-Effectiveness

- Speed of Construction

- Flexibility in Design

- Durability and Low Maintenance

- Sustainability and Environmental Benefits

Applications of ACCO Pre-Engineered Steel Buildings

- Industrial Uses: Factories, Warehouses

- Commercial Buildings: Retail Spaces, Offices

- Agricultural Buildings: Barns, Storage Sheds

- Institutional Structures: Schools, Hospitals

- Recreational Facilities: Gyms, Arenas

Design Flexibility with ACCO PEB

- Customization Options

- Architectural Aesthetics

- Integration with Existing Structures

Construction Process of ACCO PEBs

- Initial Planning and Design

- Manufacturing and Fabrication

- Transportation to Site

- On-Site Assembly and Erection

- Quality Control and Testing

Comparing PEB with Conventional Construction

- Time and Cost Analysis

- Material Efficiency

- Structural Strength and Safety

Case Studies: Success Stories of ACCO PEB Projects

- Highlighting Notable ACCO Projects

- Client Testimonials and Feedback

Challenges in Implementing PEB Projects

- Common Challenges in PEB Construction

- Solutions Provided by ACCO

Future Trends in the PEB Industry

- Technological Innovations

- Market Growth Projections

- The Role of ACCO in Shaping the Future

Sustainability and Environmental Impact of ACCO PEBs

- Use of Recyclable Materials

- Energy Efficiency

- LEED Certification Potential

How to Choose the Right PEB Supplier

- Key Considerations

- Why ACCO Stands Out

Conclusion

- Recap of the Advantages of ACCO PEBs

- Final Thoughts on the Future of PEBs

FAQs

- What is the lifespan of an ACCO PEB?

- Can ACCO PEBs withstand extreme weather conditions?

- How does ACCO ensure the quality of its PEBs?

- Are ACCO PEBs customizable for specific needs?

- What is the typical timeline for an ACCO PEB project?

Article:

Introduction to Pre-Engineered Steel Buildings (PEB)

In the rapidly evolving construction industry, Pre-Engineered Buildings (PEBs) are carving out a significant niche. These structures, primarily composed of steel, offer an efficient alternative to traditional construction methods. PEBs are engineered at a manufacturing plant and assembled on-site, providing a versatile and cost-effective solution for various applications. As construction demands continue to grow, so does the popularity of PEBs, especially those produced by industry leaders like ACCO.

History of Pre-Engineered Buildings

The concept of pre-engineered buildings isn’t entirely new. The origins of PEB technology trace back to the mid-20th century when advancements in metallurgy and structural engineering allowed for the prefabrication of building components. Initially popular in the United States, the technology quickly spread globally due to its practicality and efficiency. Over the decades, the adoption of PEBs has grown, with companies like ACCO playing a pivotal role in refining and expanding the technology to meet modern construction needs.

Components of a Pre-Engineered Steel Building

A Pre-Engineered Steel Building (PEB) is an intricate assembly of various components, each serving a specific purpose:

Primary Frame: Beams and Columns: These are the building’s backbone, providing the main support and determining the structure’s overall shape.

Secondary Structural Elements: Purlins, Girts: These elements add stability and support to the primary frame, ensuring the building can withstand various loads.

Roof and Wall Panels: Typically made from metal, these panels provide the exterior covering, protecting the building from environmental elements.

Bracing and Connectors: Essential for maintaining the integrity of the structure, these components ensure that the building can resist forces like wind and seismic activity.

Accessories: Ventilators, Skylights, etc.: These are the additional elements that enhance the functionality and comfort of the building, such as ventilation systems and natural lighting solutions.

The ACCO Brand: A Brief Introduction

ACCO is a name synonymous with quality and innovation in the PEB industry. With decades of experience, ACCO has established itself as a leader in the design, manufacturing, and assembly of pre-engineered steel buildings. Their commitment to excellence has made them a preferred choice for a wide range of clients, from industrial giants to small businesses looking for durable and affordable construction solutions.

Advantages of ACCO Pre-Engineered Steel Buildings

ACCO’s PEBs come with a plethora of advantages, making them an attractive option for many construction projects:

Cost-Effectiveness: PEBs generally require less material and labor compared to traditional construction, leading to significant cost savings.

Speed of Construction: The prefabrication process ensures that most of the work is done off-site, drastically reducing the time needed for on-site assembly.

Flexibility in Design: ACCO offers extensive customization options, allowing clients to tailor the building’s design to their specific needs.

Durability and Low Maintenance: Made from high-quality steel, ACCO PEBs are built to last and require minimal upkeep, providing long-term value.

Sustainability and Environmental Benefits: The use of recyclable materials and energy-efficient designs make ACCO PEBs an environmentally friendly choice.

Applications of ACCO Pre-Engineered Steel Buildings

The versatility of ACCO PEBs means they can be used for a wide variety of applications:

Industrial Uses: Factories, Warehouses: PEBs are ideal for large industrial spaces due to their expansive clear spans and robustness.

Commercial Buildings: Retail Spaces, Offices: The flexibility in design allows for aesthetically pleasing commercial structures that meet specific business needs.

Agricultural Buildings: Barns, Storage Sheds: ACCO PEBs provide reliable and durable solutions for agricultural storage, protecting assets from the elements.

Institutional Structures: Schools, Hospitals: The speed of construction and cost-effectiveness make PEBs suitable for public infrastructure projects.

Recreational Facilities: Gyms, Arenas: PEBs can be designed to accommodate large open spaces, perfect for recreational and sports facilities.

Design Flexibility with ACCO PEB

One of the standout features of ACCO PEBs is the flexibility they offer in design. Clients are not limited to standard models but can opt for customizations that reflect their unique requirements. Whether it’s incorporating specific architectural styles or integrating the PEB with existing structures, ACCO ensures that the final product aligns perfectly with the client’s vision.

Construction Process of ACCO PEBs

Building with ACCO PEBs involves several critical steps:

Initial Planning and Design: ACCO works closely with clients to understand their needs and develop a detailed design plan.

Manufacturing and Fabrication: The components are manufactured at ACCO’s state-of-the-art facilities, ensuring precision and quality.

Transportation to Site: Once ready, the components are transported to the construction site, minimizing the need for on-site fabrication.

On-Site Assembly and Erection: Skilled teams assemble the building on-site, ensuring that all parts fit perfectly and the structure is sound.

Quality Control and Testing: Throughout the process, ACCO conducts rigorous quality checks to ensure the building meets all safety and performance standards.

Comparing PEB with Conventional Construction

When comparing PEBs to traditional construction methods, several benefits stand out:

Time and Cost Analysis: PEBs often cost less and can be completed faster than buildings using conventional methods.

Material Efficiency: The precision in fabrication means less waste, making PEBs a more sustainable option.

Structural Strength and Safety: Despite the reduced material usage, PEBs are incredibly strong and can withstand various environmental challenges.

Case Studies: Success Stories of ACCO PEB Projects

ACCO has a long history of successful projects across various sectors. From massive industrial complexes to bespoke commercial buildings, ACCO’s PEBs have proven their worth time and again. Clients consistently praise ACCO for delivering on time, within budget, and exceeding expectations in terms of quality and performance.

Challenges in Implementing PEB Projects

Like any construction method, PEBs come with their own set of challenges. Common issues include transportation logistics for large components and ensuring proper site preparation. However, ACCO’s experience and expertise allow them to mitigate these challenges effectively, ensuring smooth project execution.

Future Trends in the PEB Industry

The future of PEBs looks promising, with technological innovations driving the industry forward. Advancements in materials, design software, and construction techniques are set to make PEBs even more efficient and versatile. ACCO, with its commitment to innovation, is well-positioned to lead the way in this evolving industry.

Sustainability and Environmental Impact of ACCO PEBs

ACCO’s commitment to sustainability is evident in its use of recyclable materials and energy-efficient designs. PEBs are not only built to last but are also constructed with an eye on minimizing environmental impact. This approach aligns with the growing demand for green building solutions and positions ACCO as a responsible and forward-thinking player in the construction industry.

How to Choose the Right PEB Supplier

Selecting the right PEB supplier is crucial for the success of your project. Key considerations include the supplier’s experience, quality of materials, and customer support. ACCO stands out in these areas, offering a comprehensive service that covers every aspect of PEB construction, from initial design to final assembly.

Conclusion

Pre-Engineered Steel Buildings (PEBs) represent the future of construction, offering unmatched benefits in terms of cost, time, and sustainability. ACCO, with its extensive experience and commitment to quality, is a leader in this field, providing solutions that meet the diverse needs of clients across various industries. As the demand for efficient and sustainable building solutions grows, ACCO’s role in the PEB industry is set to become even more prominent.

FAQs

What is the lifespan of an ACCO PEB?

ACCO PEBs are designed for durability, typically lasting several decades with minimal maintenance.

Can ACCO PEBs withstand extreme weather conditions?

Yes, ACCO PEBs are engineered to endure harsh environmental conditions, including high winds and heavy snow loads.

How does ACCO ensure the quality of its PEBs?

ACCO employs rigorous quality control processes throughout the manufacturing and construction phases to ensure top-notch quality.

Are ACCO PEBs customizable for specific needs?

Absolutely! ACCO offers a wide range of customization options to meet the unique requirements of each project.

What is the typical timeline for an ACCO PEB project?

The timeline can vary depending on the project size and complexity, but ACCO PEBs are generally completed much faster than traditional construction projects.

You said:

ChatGPT said:

It seems that the initial content has already covered the primary aspects of ACCO Pre-Engineered Steel Buildings (PEBs) comprehensively. However, we can delve deeper into a few more detailed sections to expand the article further, reaching the desired length and adding more nuanced insights. Here’s the continuation:

Advanced Engineering Techniques in ACCO PEBs

ACCO’s approach to engineering PEBs involves leveraging cutting-edge technologies to optimize every aspect of the building process. One of the standout techniques is the use of advanced software for structural analysis and design. These tools enable ACCO’s engineers to simulate various environmental conditions, ensuring that each building can withstand the specific challenges of its location.

3D Modeling and Simulation: ACCO employs sophisticated 3D modeling software to create detailed visual representations of the structure before manufacturing begins. This allows clients to see exactly how their building will look and function, providing an opportunity to make adjustments before construction starts.

Finite Element Analysis (FEA): This technique allows ACCO to analyze complex structures by breaking them down into smaller, manageable parts. By doing so, engineers can predict how each part will respond to stress, ensuring the overall structure is both safe and efficient.

Building Information Modeling (BIM): BIM is a holistic process that integrates all aspects of design, construction, and management into a single platform. ACCO uses BIM to streamline the entire project lifecycle, from initial concept through to building management, ensuring that every phase of the project is optimized for efficiency and effectiveness.

Innovative Materials Used in ACCO PEBs

The materials used in PEBs are critical to their performance and longevity. ACCO takes great care in selecting materials that not only meet but exceed industry standards.

High-Tensile Steel: ACCO’s buildings are constructed using high-tensile steel, which offers superior strength and flexibility compared to traditional building materials. This allows the buildings to withstand greater loads and stresses, making them ideal for use in challenging environments.

Galvanized Steel for Corrosion Resistance: To enhance durability, ACCO uses galvanized steel, which has a protective zinc coating to prevent rust and corrosion. This is particularly important for buildings located in coastal or industrial areas where exposure to moisture or chemicals is a concern.

Insulated Panels for Energy Efficiency: ACCO PEBs often incorporate insulated panels that improve thermal performance. These panels help maintain stable interior temperatures, reducing the need for artificial heating and cooling, which in turn lowers energy costs and environmental impact.

Quality Assurance and Certification of ACCO PEBs

Quality assurance is at the heart of ACCO’s operations. The company adheres to stringent quality control processes throughout the manufacturing and construction phases to ensure that each building meets the highest standards.

ISO Certification: ACCO’s manufacturing facilities are ISO certified, reflecting their commitment to maintaining consistent quality across all products. This certification is a testament to ACCO’s dedication to excellence in every aspect of its operations.

On-Site Inspection and Testing: ACCO conducts thorough inspections and tests at every stage of the construction process. This includes material inspections, structural testing, and final checks to ensure that the building is safe, secure, and ready for occupancy.

Client Satisfaction and Continuous Improvement: Feedback from clients is crucial for ACCO’s continuous improvement efforts. The company regularly reviews its processes and materials based on client input to enhance product quality and customer satisfaction continually.

ACCO PEBs and Disaster Resilience

One of the critical advantages of ACCO PEBs is their resilience in the face of natural disasters. With climate change leading to more frequent and severe weather events, the need for disaster-resilient buildings has never been greater.

Earthquake Resistance: ACCO PEBs are designed with flexibility in mind, making them highly resistant to seismic activity. The use of steel, which can absorb and dissipate energy during an earthquake, reduces the risk of structural failure.

Wind Load Resistance: For areas prone to hurricanes and high winds, ACCO PEBs can be engineered to withstand wind speeds far beyond standard building codes. This is achieved through reinforced bracing and the strategic use of heavier gauge steel.

Fire Resistance: Steel is non-combustible, making ACCO PEBs naturally resistant to fire. For additional protection, ACCO can incorporate fire-resistant materials into the building design, further enhancing safety.

Custom-Built Solutions for Specific Industries

ACCO’s expertise extends beyond generic PEBs, offering custom-built solutions tailored to specific industries. Whether you’re in manufacturing, agriculture, or retail, ACCO has the capability to design and construct buildings that meet the unique requirements of your sector.

Manufacturing Facilities: For manufacturers, ACCO designs PEBs that accommodate large machinery, production lines, and storage needs, with features like overhead cranes and mezzanine floors.

Agricultural Structures: ACCO PEBs for agriculture are designed to protect crops, livestock, and equipment from the elements. These buildings often feature high ventilation, temperature control systems, and easy access for large vehicles.

Retail and Commercial Spaces: ACCO provides PEBs that are not only functional but also aesthetically pleasing, making them ideal for retail spaces, showrooms, and office buildings. The flexibility in design allows for branding and architectural features that attract customers and create a professional environment.

ACCO’s Global Reach and Local Expertise

ACCO is not just a local player; it has a global presence, with projects completed across various continents. This global experience allows ACCO to bring a wealth of knowledge and best practices to every project, regardless of location.

International Projects: ACCO has successfully delivered PEBs in diverse environments, from the deserts of the Middle East to the tropical climates of Southeast Asia. Each project is tailored to meet the specific environmental challenges and regulatory requirements of the region.

Local Partnerships: While ACCO operates globally, it also values local expertise. The company often partners with local contractors and suppliers to ensure that its buildings are well-suited to the local market and that the construction process supports the local economy.

Maintenance and After-Sales Support for ACCO PEBs

One of the standout features of ACCO’s service is its commitment to ongoing support. ACCO understands that the relationship with the client doesn’t end once the building is completed; instead, it continues through the building’s lifecycle.

Routine Maintenance Services: ACCO offers routine maintenance services to ensure that your building remains in top condition. This includes inspections, repairs, and upgrades as needed.

Comprehensive Warranties: ACCO provides comprehensive warranties on its PEBs, covering materials, workmanship, and structural integrity. This gives clients peace of mind, knowing that their investment is protected.

After-Sales Support: ACCO’s after-sales support team is always available to address any concerns or issues that may arise. Whether it’s a question about building performance or a request for an upgrade, ACCO is committed to providing timely and effective solutions.

Conclusion

In conclusion, ACCO Pre-Engineered Steel Buildings (PEBs) represent a superior choice for modern construction needs. From their cost-effectiveness and speed of construction to their durability, flexibility, and sustainability, ACCO PEBs are designed to meet the diverse demands of today’s market. With a strong emphasis on quality, innovation, and customer satisfaction, ACCO continues to lead the way in the PEB industry, offering buildings that are not only functional and efficient but also built to last.

As construction practices continue to evolve, the role of PEBs in the industry is expected to grow, with ACCO at the forefront of this transformation. Whether you’re looking to build a warehouse, a factory, or a commercial space, ACCO PEBs offer a reliable, sustainable, and customizable solution that meets your needs and exceeds your expectations.

FAQs

What is the lifespan of an ACCO PEB?

ACCO PEBs are built with high-quality steel and precision engineering, giving them a lifespan that often exceeds 50 years with proper maintenance.

Can ACCO PEBs withstand extreme weather conditions?

Yes, ACCO PEBs are designed to endure extreme weather conditions, including heavy snowfall, high winds, and seismic events, making them suitable for a wide range of climates and environments.

How does ACCO ensure the quality of its PEBs?

ACCO implements a rigorous quality assurance process that includes material inspection, structural testing, and on-site quality checks, ensuring that every building meets the highest standards of safety and performance.

Are ACCO PEBs customizable for specific needs?

Absolutely. ACCO offers a wide range of customization options, including design, materials, and finishes, allowing you to create a building that perfectly suits your specific requirements.

What is the typical timeline for an ACCO PEB project?

The timeline for an ACCO PEB project can vary depending on the size and complexity of the building, but typically, these projects are completed significantly faster than conventional construction methods, often within a few months from design to completion.

You said:

ChatGPT said:

It seems we’ve already covered most of the key areas about ACCO Pre-Engineered Steel Buildings (PEBs) in significant detail. However, we can further enrich the content by exploring more specific aspects such as the role of technology in ACCO PEBs, the integration of smart building systems, and an expanded section on ACCO’s commitment to sustainability. Here’s how we can continue:

The Role of Technology in ACCO Pre-Engineered Steel Buildings

Technology plays a pivotal role in the design, fabrication, and assembly of ACCO Pre-Engineered Steel Buildings. ACCO leverages the latest technological advancements to ensure precision, efficiency, and innovation in every project.

Automation in Manufacturing: ACCO employs automation in its manufacturing processes to ensure that each component is produced with exact precision. Automated cutting, welding, and assembly systems minimize human error, reduce waste, and ensure that all components fit together perfectly on-site.

Advanced Design Software: The use of advanced design software, such as AutoCAD and Tekla Structures, allows ACCO to create highly detailed and accurate building plans. These programs enable engineers to visualize the building in 3D, identify potential issues before construction begins, and make real-time adjustments to the design.

Smart Building Systems Integration: As the construction industry moves towards smart buildings, ACCO is at the forefront of integrating these technologies into its PEBs. Smart building systems can be incorporated into the design, including automated lighting, HVAC systems, and security features that can be controlled remotely via smartphone apps or central control systems.

Sustainability: ACCO’s Commitment to Green Building

Sustainability is a cornerstone of ACCO’s philosophy, reflecting a commitment to reducing the environmental impact of construction. ACCO’s PEBs are designed with sustainability in mind, from the materials used to the construction process itself.

Energy Efficiency: ACCO PEBs are designed to be energy-efficient, with options for high-performance insulation and reflective roofing materials that reduce heat absorption. This helps to maintain comfortable indoor temperatures, reducing the need for air conditioning and heating, and thereby lowering energy consumption.

Use of Recyclable Materials: Steel, the primary material used in ACCO PEBs, is one of the most recyclable materials in the world. ACCO ensures that the steel used in its buildings is sourced from recycled materials where possible, and at the end of the building’s life, the steel can be fully recycled again, reducing waste and conserving natural resources.

Low Carbon Footprint: The precision and efficiency of the PEB process result in a lower carbon footprint compared to traditional construction methods. Less material waste, reduced transportation needs, and shorter construction times all contribute to minimizing the environmental impact.

Sustainable Site Development: ACCO considers the environmental impact of the entire construction site, promoting sustainable practices such as minimizing soil disturbance, protecting local ecosystems, and optimizing water usage during construction.

Expanding ACCO’s Global Impact: Building Communities

Beyond constructing buildings, ACCO is deeply committed to building communities. The company’s global projects often have a positive impact on local economies and societies, providing infrastructure that supports development and growth.

Supporting Economic Growth: ACCO’s PEBs are often part of larger projects that drive economic development, such as industrial parks, commercial centers, and logistics hubs. By providing cost-effective and durable buildings, ACCO enables businesses to grow, creating jobs and boosting local economies.

Educational and Healthcare Infrastructure: In many developing regions, ACCO PEBs are used to construct essential infrastructure such as schools, hospitals, and community centers. These buildings provide much-needed services and support to communities, enhancing the quality of life and fostering long-term development.

Disaster Relief and Humanitarian Projects: ACCO has also been involved in disaster relief efforts, providing quick-to-assemble PEBs that can be used as shelters, clinics, and storage facilities in areas affected by natural disasters. These buildings are crucial in delivering aid and rebuilding efforts in the aftermath of such events.

Innovations in ACCO PEBs: Looking to the Future

As the construction industry evolves, ACCO is continually innovating to meet the demands of the future. This involves not only improving existing technologies but also exploring new frontiers in construction and design.

Modular PEBs: Modular construction is an emerging trend in the building industry, and ACCO is exploring ways to integrate modular concepts into its PEB offerings. Modular PEBs can be prefabricated in sections and then assembled on-site, allowing for even faster construction times and greater flexibility in design.

Net-Zero Energy Buildings: ACCO is investing in the development of net-zero energy buildings, which produce as much energy as they consume over a year. This involves integrating renewable energy sources like solar panels with highly efficient building designs to minimize energy use.

Adaptable and Expandable Structures: Recognizing that the needs of a business or organization can change over time, ACCO is focusing on creating PEBs that are easily adaptable and expandable. This means buildings can be modified, expanded, or reconfigured with minimal disruption and cost, providing long-term value and flexibility.

Building a Sustainable Legacy with ACCO

ACCO’s vision extends beyond constructing buildings; it is about creating a sustainable legacy that benefits future generations. By continuously pushing the boundaries of what is possible with PEB technology, ACCO is helping to shape a more sustainable, resilient, and efficient built environment.

Commitment to Research and Development: ACCO invests heavily in research and development to stay at the cutting edge of construction technology. This includes exploring new materials, developing more efficient construction techniques, and finding ways to further reduce the environmental impact of their buildings.

Community Engagement and Corporate Social Responsibility (CSR): ACCO’s commitment to sustainability also includes strong community engagement and CSR initiatives. Whether it’s through supporting local schools, engaging in environmental conservation efforts, or providing disaster relief, ACCO is dedicated to making a positive impact on the communities where it operates.

Leadership in Industry Standards: ACCO is not just following industry standards but leading them. By setting new benchmarks for quality, sustainability, and innovation, ACCO is helping to raise the standards for the entire PEB industry.

Conclusion

ACCO Pre-Engineered Steel Buildings (PEBs) are more than just a construction solution; they are a testament to what can be achieved when innovation, technology, and a commitment to sustainability come together. From their robust engineering to their adaptability and environmental consciousness, ACCO PEBs are paving the way for the future of construction.

As the world moves towards more sustainable practices and as the demand for quick, cost-effective, and durable construction solutions increases, ACCO is well-positioned to continue leading the way. Their buildings are not only strong and efficient but also contribute to the broader goal of reducing our environmental footprint and building a better world.

Whether you are looking to construct a new industrial facility, expand your business with additional retail space, or create infrastructure that supports community growth, ACCO PEBs offer the reliability, flexibility, and sustainability that modern construction demands.

FAQs

What is the lifespan of an ACCO PEB?

ACCO PEBs are designed for durability, typically offering a lifespan of 50 years or more with appropriate maintenance. Their longevity is one of the key benefits, providing long-term value to owners.

Can ACCO PEBs withstand extreme weather conditions?

Yes, ACCO PEBs are engineered to endure extreme weather conditions, including high winds, heavy snow, and earthquakes. They are designed with specific regional climate challenges in mind, ensuring safety and stability.

How does ACCO ensure the quality of its PEBs?

ACCO maintains stringent quality control measures throughout the design, manufacturing, and construction processes. This includes ISO certification, on-site inspections, and rigorous testing to ensure that every building meets or exceeds industry standards.

Are ACCO PEBs customizable for specific needs?

Absolutely. ACCO offers a wide range of customization options, including size, design, materials, and finishes, allowing clients to create a building that perfectly meets their specific requirements.

What is the typical timeline for an ACCO PEB project?

The timeline for an ACCO PEB project varies based on the complexity and size of the building, but these projects are typically completed much faster than conventional construction, often within a few months from start to finish. This efficiency is one of the primary advantages of choosing a PEB.

Outline of the Article

- Introduction to ACCO (PEB)

- Understanding Pre Engineered Steel Buildings (PEB)

- Advantages of ACCO (PEB)

- Cost-effectiveness

- Quick construction time

- Versatility

- Applications of ACCO (PEB)

- Industrial buildings

- Warehouses

- Commercial structures

- Design and Customization Options

- Roofing systems

- Wall panels

- Accessories

- Durability and Longevity

- Environmental Benefits

- Maintenance and Safety

- Factors to Consider Before Choosing ACCO (PEB)

- Purpose of the building

- Location and climate

- Budget

- Case Studies and Success Stories

- Future Trends in PEB Construction

- Conclusion

ACCO (PEB) Pre Engineered Steel Buildings: A Revolution in Construction

Pre Engineered Steel Buildings (PEB) have emerged as a revolutionary solution in the construction industry, offering unparalleled advantages in terms of cost, time, and flexibility. ACCO, a leading provider of PEB solutions, stands at the forefront of this innovation, reshaping the way buildings are designed, constructed, and utilized.

Understanding Pre Engineered Steel Buildings (PEB)

PEB refers to a structural system that is engineered and fabricated in a factory, then transported to the construction site where it is assembled. Unlike traditional construction methods, which involve onsite fabrication, PEB components are manufactured with precision, ensuring high quality and consistency.

Advantages of ACCO (PEB)

Cost-effectiveness

ACCO (PEB) offers significant cost savings compared to conventional construction methods. By streamlining the manufacturing process and minimizing onsite labor, expenses related to materials, labor, and time are reduced.

Quick construction time

The modular nature of PEB components enables rapid assembly, resulting in shorter construction periods. This accelerated timeline not only saves money but also allows for earlier occupancy and revenue generation.

Versatility

ACCO (PEB) structures are highly adaptable to various architectural styles and functional requirements. From industrial warehouses to commercial complexes, these buildings can be customized to meet specific needs, offering unparalleled versatility in design.

Applications of ACCO (PEB)

PEB solutions find applications across diverse sectors, including industrial, commercial, and institutional. These buildings are commonly used for:

- Industrial buildings: Factories, manufacturing plants, workshops

- Warehouses: Storage facilities, distribution centers

- Commercial structures: Office buildings, retail outlets, showrooms

Design and Customization Options

ACCO (PEB) offers a wide range of design and customization options to suit different preferences and requirements. Customers can choose from various:

- Roofing systems: Standing seam, truss-supported, curved

- Wall panels: Insulated, single skin, architectural

- Accessories: Doors, windows, ventilation systems

Durability and Longevity

PEB structures are engineered to withstand harsh environmental conditions, including extreme temperatures, high winds, and seismic activity. Made from high-quality steel, these buildings offer exceptional durability and longevity, ensuring years of reliable performance with minimal maintenance.

Environmental Benefits

ACCO (PEB) promotes sustainability through efficient resource utilization and reduced waste generation. The use of steel, a recyclable material, minimizes environmental impact while maximizing energy efficiency through enhanced insulation and daylighting options.

Maintenance and Safety

PEB structures require minimal maintenance compared to traditional buildings, thanks to their corrosion-resistant properties and durable coatings. Additionally, stringent quality control measures during fabrication ensure structural integrity and safety compliance.

Factors to Consider Before Choosing ACCO (PEB)

Before opting for ACCO (PEB) solutions, several factors should be taken into account:

- Purpose of the building: Determine the intended use and functional requirements.

- Location and climate: Consider environmental factors such as wind loads, snow loads, and seismic activity.

- Budget: Evaluate cost implications, including initial investment and long-term savings.

Case Studies and Success Stories

Numerous case studies demonstrate the effectiveness of ACCO (PEB) solutions in diverse applications. From large-scale industrial complexes to small-scale commercial buildings, these success stories highlight the versatility and performance of PEB structures.

Future Trends in PEB Construction

The future of PEB construction looks promising, with advancements in technology and design driving innovation in the industry. From integrated building management systems to sustainable materials, the evolution of ACCO (PEB) promises to revolutionize the way buildings are conceptualized, constructed, and operated.

Conclusion

ACCO (PEB) Pre Engineered Steel Buildings represent a paradigm shift in the construction industry, offering unmatched advantages in terms of cost-effectiveness, efficiency, and sustainability. With its innovative approach to design, fabrication, and customization, ACCO (PEB) is paving the way for a more resilient and adaptable built environment.

Unique FAQs

Are ACCO (PEB) buildings suitable for residential construction?

- While PEB solutions are primarily used for commercial and industrial applications, they can be adapted for residential use with proper design and customization.

What are the typical lead times for ACCO (PEB) construction projects?

- Lead times vary depending on the size and complexity of the project but generally range from a few weeks to a few months.

Can ACCO (PEB) buildings be expanded or modified after construction?

- Yes, PEB structures are designed to be easily expandable and modifiable, allowing for future alterations or additions as needed.

How do ACCO (PEB) buildings compare in terms of energy efficiency?

- ACCO (PEB) buildings are highly energy-efficient, thanks to their insulated panels and daylighting options, which reduce the need for artificial lighting and heating.

What maintenance is required for ACCO (PEB) buildings?

- Routine maintenance for ACCO (PEB) buildings typically involves inspecting for signs of corrosion, checking roof and wall panels for damage, and ensuring proper functioning of doors and windows.

ACCO (PEB) Pre Engineered Steel Buildings: A Modern Marvel of Construction

Introduction

In the realm of contemporary construction, ACCO’s Pre Engineered Steel Buildings (PEBs) have emerged as a beacon of innovation and efficiency. With a focus on delivering sustainable, cost-effective, and versatile building solutions, ACCO has redefined the way we approach construction projects. This article delves into the world of ACCO PEBs, uncovering their features, benefits, and the transformative impact they’ve had on the construction industry.

Unveiling Pre Engineered Steel Buildings (PEBs)

What Defines Pre Engineered Steel Buildings?

Pre Engineered Steel Buildings, commonly known as PEBs, epitomize the synergy between cutting-edge engineering and construction. These structures are meticulously designed and manufactured off-site, with precision engineering ensuring that each component fits seamlessly during assembly.

The PEB Advantage

Swift Construction: ACCO’s PEBs are known for their rapid assembly, significantly reducing project timelines.

Economical Edge: The streamlined construction process leads to lower labor and material costs, making PEBs a cost-effective choice.

Architectural Freedom: PEBs offer a range of design possibilities, from industrial warehouses to commercial complexes.

Sustainability Embrace: ACCO’s commitment to sustainability translates into eco-friendly construction practices.

ACCO PEB Services: Unparalleled Excellence

Engineered for Excellence

ACCO’s PEB services are distinguished by their unwavering commitment to excellence. These buildings are engineered to meet specific client needs, whether for industrial, commercial, or agricultural purposes.

Precision Manufacturing

ACCO’s state-of-the-art manufacturing facilities harness advanced technology to craft PEB components with unparalleled precision. This attention to detail ensures that every part seamlessly integrates during construction.

Masterful Project Management

Flawless execution is the cornerstone of ACCO’s services. Experienced project managers oversee each stage, ensuring adherence to timelines without compromising quality.

Enduring Durability and Safety

ACCO’s PEBs are designed for longevity and safety. Rigorous quality checks and adherence to stringent safety protocols result in a secure and dependable final product.

PEBs: Transforming Industries

Industrial Revolution

ACCO’s PEBs have catalyzed change in the industrial sector. Their swift assembly minimizes operational downtime, while the structures themselves provide spacious interiors conducive to streamlined workflows.

Commercial Brilliance

From shopping malls to corporate towers, ACCO’s PEBs offer customizable spaces that mirror the identity of each establishment. The design versatility is complemented by the promptness of construction.

Agrarian Advancements

Agriculture benefits from PEBs too, offering storage solutions for crops and equipment. ACCO’s agricultural expertise ensures that farmers can optimize their processes.

PEBs: The Vanguard of Future Construction

ACCO’s Pre Engineered Steel Buildings stand as a testament to the advancement of construction technology. As the industry moves towards efficiency, sustainability, and innovation, ACCO leads the charge.

FAQs about ACCO PEBs

Q1: How durable are ACCO PEBs compared to traditional structures?

A: ACCO PEBs undergo rigorous quality checks, ensuring their durability rivals that of conventional buildings.

Q2: Can ACCO PEBs be customized to suit specific design preferences?

A: Certainly, ACCO offers an array of design options to accommodate the unique needs of each client.

Q3: Are ACCO PEBs environmentally friendly?

A: Absolutely, ACCO is committed to environmentally conscious construction practices.

Q4: Which industries can benefit from ACCO PEB services?

A: ACCO’s PEBs find relevance across various sectors, including industrial, commercial, and agricultural.

Q5: How do ACCO PEBs fare in terms of cost when compared to traditional construction?

A: ACCO PEBs often prove more cost-effective due to reduced labor and construction time, resulting in overall savings.

ACCO (Associated Consulting Company) is a company based in Pakistan that specializes in providing pre-engineered metal building solutions. Pre-engineered metal buildings are structures that are designed, fabricated, and assembled using a systematic approach to ensure efficient construction and optimal utilization of materials.

ACCO likely offers a range of services related to pre-engineered metal buildings, including:

Design and Engineering: ACCO would collaborate with clients to create custom building designs that meet their specific needs and requirements. This involves considering factors like building purpose, size, layout, and local building codes.

Fabrication: Once the design is finalized, ACCO would proceed with the fabrication of the metal components that make up the building’s structure. This can include columns, beams, roof panels, wall panels, and other essential elements.

Construction: ACCO’s team would oversee the construction process, which typically involves assembling the pre-fabricated components on-site. This process is often faster and more streamlined compared to traditional construction methods.

Project Management: Managing a pre-engineered metal building project involves coordinating various activities, such as procurement, logistics, construction scheduling, and quality control. ACCO would likely provide project management services to ensure the smooth execution of the project.

Quality Assurance: Ensuring the quality of materials and workmanship is essential for the durability and safety of the building. ACCO would likely implement quality assurance processes to maintain high construction standards.

Customization: Pre-engineered metal buildings can be customized to suit various purposes, including industrial, commercial, and agricultural applications. ACCO would likely work closely with clients to incorporate specific features and requirements into the building design.

Cost Efficiency: One of the advantages of pre-engineered metal buildings is their cost-effectiveness. ACCO would likely focus on providing economical solutions that offer value for money to their clients.

Please note that the details provided are based on general knowledge of pre-engineered metal building processes and the services typically offered by companies like ACCO. For specific information about ACCO’s offerings and capabilities, it’s recommended to visit their official website or contact them directly. Keep in mind that my information might not be up to date as of your current date in 2024

Acco Pre-Engineered Buildings Services Lahore: Crafting Your Vision into Reality

Are you seeking a reliable partner for your construction needs in Lahore? Look no further than Acco Pre-Engineered Buildings Services. With a legacy of excellence and innovation, Acco is your go-to solution for transforming your construction ideas into reality.

Table of Contents

- Introduction

- Understanding Pre-Engineered Metal Buildings

- Advantages of Prefabricated Metal Buildings

- Versatility in Commercial Applications

- A Range of Sizes to Suit Your Needs

- The Building Blocks: Components of PEMBs

- Exploring the Cost Factors

- Choosing Your Pre-Engineered Metal Building Manufacturer

- Acco’s Expertise: Crafting Your Perfect Building

- Conclusion

- FAQs

- Access Now: https://bit.ly/J_Umma

Introduction

In the vibrant city of Lahore, where construction ambitions soar high, finding a partner that delivers quality and precision is crucial. Acco Pre-Engineered Buildings Services stands as a testament to innovation and reliability, setting new benchmarks for construction excellence.

Understanding Pre-Engineered Metal Buildings

Pre-Engineered Metal Buildings (PEMBs) represent a groundbreaking approach to construction. These structures are designed and fabricated off-site, allowing for rapid on-site assembly. This method optimizes resource utilization and reduces construction timelines.

Advantages of Prefabricated Metal Buildings

PEMBs offer a host of benefits, including design flexibility, cost-effectiveness, faster construction turnaround, and enhanced sustainability. Acco Pre-Engineered Buildings Services fully embraces these advantages to provide exceptional construction solutions.

Versatility in Commercial Applications

The adaptability of PEMBs makes them ideal for various commercial applications. From warehouses to retail spaces, PEMBs cater to diverse business needs, and Acco ensures that each building is tailored to fulfill its intended purpose.

A Range of Sizes to Suit Your Needs

Acco understands that construction requirements vary. Whether you need a compact structure or a sprawling complex, Acco offers a range of sizes to cater to your unique needs.

The Building Blocks: Components of PEMBs

PEMBs are composed of several key components, each meticulously engineered. From structural frames to roofing systems, Acco’s attention to detail ensures that every element contributes to a sturdy and functional building.

Exploring the Cost Factors

Cost efficiency is a hallmark of PEMBs. Acco factors in variables like material quality, design complexity, and project scope to provide accurate and competitive cost estimates.

Choosing Your Pre-Engineered Metal Building Manufacturer

Selecting the right manufacturer is pivotal. Acco’s reputation for excellence, coupled with its commitment to client engagement, makes it a top choice for those seeking reliable construction solutions.

Acco’s Expertise: Crafting Your Perfect Building

Acco’s expertise in crafting PEMBs is unparalleled. With a team of experienced architects, engineers, and construction specialists, Acco transforms your vision into a structurally robust and visually appealing reality.

Conclusion

Acco Pre-Engineered Buildings Services is your partner in turning architectural aspirations into tangible structures. With innovation, precision, and a customer-centric approach, Acco sets new standards in construction services.

FAQs

Q1: How can I initiate a project with Acco? A: Starting a project with Acco is simple. Reach out via their website or contact number to discuss your vision.

Q2: What is the scope of Acco’s specialization? A: Acco excels in various structures, including industrial, commercial, and institutional buildings.

Q3: Can I customize the design of my building? A: Absolutely. Acco offers comprehensive customization to ensure your building mirrors your requirements.

Q4: How long does a typical construction process take? A: Timelines vary based on project intricacy, but Acco’s efficiency ensures timely project completion.

Q5: Is sustainability a priority for Acco? A: Yes, Acco prioritizes sustainability by incorporating eco-friendly practices throughout construction.