Key Considerations in Planning a Textile Mill: A Comprehensive Guide

The construction of a textile mill is a significant investment that requires meticulous planning and consideration. It involves not just the physical construction of the building but also the integration of complex machinery, efficient workflows, and sustainable practices. At Ahmed Construction Company, we understand the importance of these factors in creating a successful textile manufacturing facility. In this blog, we will explore the key considerations in planning a textile mill to ensure that it operates efficiently, meets regulatory standards, and supports future growth.

1. Site Selection and Assessment

Location

Choosing the right location is crucial. Factors to consider include proximity to raw materials (like cotton fields), availability of skilled labor, transportation infrastructure for shipping and receiving goods, and access to utilities such as water, electricity, and gas.

Environmental Impact

Conduct environmental impact assessments to ensure that the construction and operation of the textile mill will not adversely affect the local environment. This includes analyzing the potential for air and water pollution and implementing mitigation measures where necessary.

Zoning and Regulations

Ensure that the chosen site complies with local zoning laws and regulations. This includes obtaining necessary permits and adhering to any specific requirements for industrial facilities.

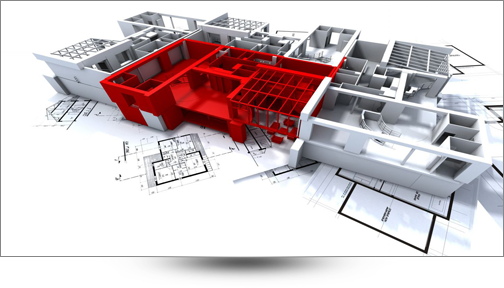

2. Design and Layout

Efficient Workflow

The design of the textile mill should facilitate an efficient workflow, minimizing the movement of materials and products between different stages of production. This can be achieved through thoughtful layout planning that considers the sequence of manufacturing processes.

Scalability

Design the facility with scalability in mind. This means creating a flexible layout that can accommodate future expansions or modifications as the business grows.

Safety and Ergonomics

Incorporate safety features into the design to protect workers and equipment. This includes proper ventilation, fire safety systems, and ergonomic workstations to reduce the risk of injuries and improve productivity.

3. Technology and Machinery

State-of-the-Art Equipment

Investing in modern, high-quality machinery is essential for producing high-quality textiles and maintaining competitive edge. Research and choose machinery that meets current industry standards and has the capability to integrate with automated systems.

Maintenance and Upgrades

Plan for regular maintenance and potential upgrades to keep machinery running efficiently and to adapt to technological advancements. This involves setting up a maintenance schedule and training staff on proper equipment care.

Energy Efficiency

Choose energy-efficient machinery and incorporate energy-saving technologies to reduce operational costs and environmental impact. This can include installing energy-efficient motors, lighting, and HVAC systems.

4. Sustainability Practices

Waste Management

Implement effective waste management strategies to handle textile waste, including recycling and proper disposal methods. Consider setting up systems for recycling water and reducing chemical waste.

Eco-Friendly Materials

Use eco-friendly construction materials and practices to minimize the environmental footprint of the textile mill. This can include sustainable building materials, energy-efficient windows, and insulation.

Certifications

Aim for sustainability certifications such as LEED (Leadership in Energy and Environmental Design) to demonstrate commitment to environmental responsibility. These certifications can also enhance the company’s reputation and marketability.

5. Financial Planning and Budgeting

Cost Estimation

Develop a comprehensive budget that includes all aspects of the project, from land acquisition and construction to machinery and initial operating costs. Ensure there is a contingency fund for unexpected expenses.

Funding and Financing

Explore different financing options, including loans, grants, and investment opportunities. Work with financial advisors to determine the best funding strategy for your project.

Return on Investment (ROI)

Analyze the potential ROI by considering factors such as production capacity, market demand, and operational costs. This will help in making informed decisions about the scale and scope of the project.

6. Regulatory Compliance

Industry Standards

Ensure compliance with industry standards and regulations, including those related to safety, labor, and environmental impact. This includes adhering to guidelines set by organizations such as the Pakistan Environmental Protection Agency (EPA) and the International Labour Organization (ILO).

Quality Control

Implement rigorous quality control processes to meet both local and international standards. This includes setting up quality control labs and procedures for regular testing of products.

Documentation and Reporting

Maintain thorough documentation of all aspects of the project, from initial planning to daily operations. This ensures transparency and accountability and can be crucial for audits and inspections.

7. Workforce Planning

Skilled Labor

Identify and hire skilled labor required for the operation of the textile mill. This includes operators, technicians, and management personnel who are experienced in textile manufacturing.

Training and Development

Invest in training programs to ensure that all employees are knowledgeable about the latest technologies and best practices in textile manufacturing. Continuous education helps maintain high standards of quality and efficiency.

Health and Safety

Prioritize the health and safety of workers by providing proper safety equipment, conducting regular training sessions, and maintaining a safe working environment. Implement health and safety protocols that comply with national and international standards.

Conclusion

Planning a textile mill is a complex process that requires careful consideration of numerous factors. From site selection and design to technology integration and sustainability practices, each aspect plays a crucial role in the overall success of the project. At Ahmed Construction Company, we bring our extensive experience and expertise to help you navigate these challenges and build a textile mill that meets your needs and exceeds your expectations. By focusing on efficiency, quality, and sustainability, we aim to create facilities that not only thrive in today’s competitive market but also contribute positively to the future of the textile industry in Pakistan.

If you are considering constructing a textile mill in Pakistan, contact Ahmed Construction Company today to learn more about how we can assist you in turning your vision into reality.